Copper Alloys Engraving Brass C35600

|

Product Data Sheet – Copper Alloys |

Engraving Brass Alloy 356 UNS-C35600Also known as Extra High Leaded Brass |

Chemical CompositionAS2738.2-1984

Equivalent Alloy Specifications

ASTM Product Specifications

Fabrication Properties

Mechanical PropertiesASTM B121 – Leaded Brass Plate, Sheet, Strip and Rolled Bar

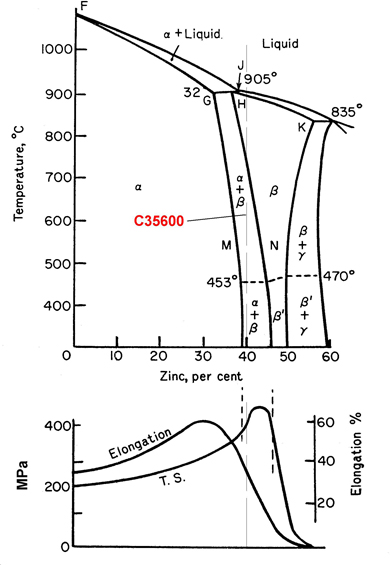

2. Annealed and hard tempers are available from stock. Other tempers available for sufficient quantities on request. Available Forms Austral Wright Metals can supply this alloy as plate, sheet and bar. General Description Engraving brass is traditionally used for machine engraved name plates due to its combination of high strength and free machining characteristics. It is an alpha / beta brass with a duplex structure which renders it unsuitable for acid etched work, for which the single phase brasses such as C26000 (70/30 brass) are preferable. C35600 weathers to the warm brown bronze tone which is desirable for name plates. C37000 is also available, with lower (0.9–1.4%) lead content. It has excellent free cutting properties, but machinability is only 70% of C35600. Typical applications are engraved name plates and plaques, appliance trim, clock components, builders hardware, gear meters, free machining sheet and plate. Physical Properties

Phase Diagram & Mechanical Properties

Corrosion ResistanceC35600 has good corrosion resistance to weathering and fair resistance to many waters. There is some risk of failure by dezincification. C35600 should not be used in contact with ammonia, ammonia compounds or amines, as it may suffer stress corrosion cracking. It is more susceptible to stress corrosion and dezincification than the single phase high copper brasses, but these are seldom a serious problem in atmospheric conditions. Please consult Austral Wright Metals for advice on your specific application. |