Copper Alloys Silicon Bronze C65500

|

Product Data Sheet – Copper Alloys |

What Is Silicon BronzeSilicon bronze is perhaps better known by its American trade name “Everdur” for silicon bronze wire and rod, or the Australian trade name “Cusilman” for silicon bronze sheet, plate, circles and ingot. International this alloy is known as UNS C65500 and nominally contains 96% copper, 3% silicon and 1% manganese. The addition of manganese greatly increases tensile yield strength, tensile strength and fatigue strengths while still retaining the excellent ductility, durability and fabricating properties characteristic of copper. Whilst not classified as a low lead brass alloy due to no zinc addition, it also has no lead addition. Despite its high strength this material has high ductility and can withstand severe cold forming if necessary. Like stainless steel, silicon bronze work hardens fairly rapidly.

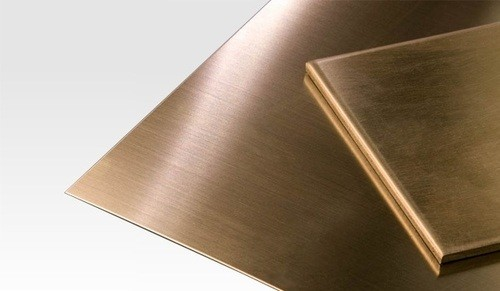

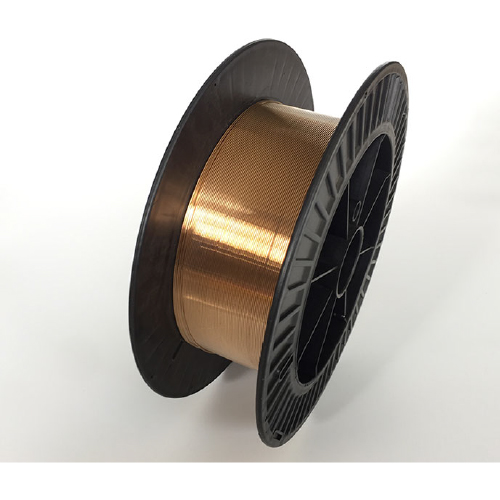

Silicon Bronze Product ExamplesPhysical Properties and Mechanical Properties of Silicon BronzeSilicon bronze is generally superior to copper in corrosive situations and finds wide use as high-strength, corrosion-resistant welded vessels. Calorifiers, domestic hot water cylinders, process vessels and pickling tanks are typical applications. The silicon content lowers the conductivity of silicon bronze drastically to that of steel and also acts as a very efficient deoxidant when the metal is molten. As a result, silicon bronze is one of the easiest copper alloys to weld which is a particular advantage in boiler and pressure vessel applications. This alloy withstands many corrosive situations involving non-oxidising environments much better than stainless steel and should be regarded as a competitor to stainless steel in many welded corrosion-resistant fabrications. Welding propertiesThe silicon bronzes are universally recognised as having the best welding properties of all the copper alloys. They are readily weldable by the Inert Gas Tungsten Arc (TIG), the Inert Gas Consumable Electrode (MIG), and the Carbon-Arc and Oxy-Acetylene processes. The Shielded Metal-Arc Process can be used, but the TIG and MIG processes are generally preferred. Even resistance welding processes can be applied to material up to 2mm thick. Silicon bronze filler metal rods and wire are commonly available. Braze welding is not a typical process used.

Corrosion propertiesAs mentioned silicon bronze has good corrosion resistance. The degree of corrosion resistance always depends on the service conditions. Variables such as temperature, fluid velocity and concentration of oxidising agents may all greatly influence the rate of corrosion. Service experience has shown that silicon bronze may be used to advantage in the following applications:

Importantly silicon bronze should not be used for the following:

Silicon Bronze and galvanic corrosionGalvanic corrosion results from contact of dissimilar metals exposed to a corrosive influence. Most of the copper alloys may be used in contact with silicon bronze with little risk of this type of corrosion. However, an all-silicon bronze structure is preferred. This includes using silicon bronze filler rods in welding which reduces the likelihood of galvanic corrosion. Silicon Bronze and stress corrosion crackingStress corrosion cracking is caused by corrosive action in combination with high localised stresses in a structure. In sections where stresses are high, sometimes even the mildest corrosive influences cause big trouble. Although silicon bronze is relatively resistant to stress corrosion cracking, there are a few corrosive agents (eg ammonia and amine type compounds) which may cause this type of attack. In structures like tanks or pressure vessels, stress might come from many directions, eg;

Service at elevated temperatureSilicon bronze is not recommended for service where temperatures are likely to exceed 150C or in contact with steam at temperatures in excess of 100C. Although the alloy can be used at higher temperatures than 150C, it is subject to creep over long periods of service. The comparatively low permissible design stresses based on creep data necessitate uneconomical thickness of plate for vessels. Short periods of service at elevated temperatures can be safely tolerated as the normal design stresses are usually based on 0.,1% of strain in 10,000 hours of service. Contact with steam or water in excess of 100C for long periods of time may produce a corrosive attack, particularly if the material is fairly highly stressed or is subject to cycling stresses. Silicon Bronze ApplicationsThis is an alloy that should be used in any application where strength and formability of mils steel are required with the corrosion resistance of copper. The strength and corrosion resistance combination is also an advantage in a wide variety of applications from marine hardware (as used in Australia’s first-ever America’s Cup entrant “GRETEL”, and fastenings to various items of chemical plants.)

Industrial Oil Refinery Plumbing Tube, Chemical Industry, Welded Tanks, Screen Cloth, Piston Rings, Kettles, Heat Exchanger Tubes, Chemical Equipment, Channels, Cable, Bushings, Bearing Plates, Butts, Shafting, Screen Plates, Wire, Doctor Blades, Paper Industry, Hydraulic Pressure Lines, Tanks, Pressure Vessels, Welded Pressure Vessels, Wear Plates, Marine Hardware, Propeller Shafts. |

Chemical Composition% Maximum, unless shown as range or minimum

(2) Nickel value includes Cobalt Note: Copper + Sum of named elements, 99.5% minimum Applicable Specifications

Common Fabrication ProcessesBlanking, Drawing, Forming and Bending, Heading and Upsetting, Hot Forging and Pressing, Roll Threading and Knurling, Shearing, Squeezing and Swaging. Fabrication Properties

Mechanical PropertiesRoom Temperature 20°C

Physical Properties

Tempers Most Commonly Used

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||