Marine Grade Stainless Steel 445M2 – Austral Wright Metals

|

Stainless Steel Brochure 445M2 |

445M2: The New Marine Grade Stainless Steel – The sensible alternative to 316 |

|  |

| |

445M2 – The improved alternative to 316 Stainless Steel |

Marine grade stainless steel 316 has been around for a long time. Now there’s an alternative, that’s even better – grade 445M2 from Austral Wright Metals. Developed in Japan, with a successful track record in Australasia, 445M2 offers real advantages over grade 316. |

Unlike 316 stainless steel, 445M2 has a ferritic microstructure, and a higher content of the corrosion resisting element, chromium. That gives it some big technical benefits over 316 marine grade stainless: • Better resistance to atmospheric corrosion & pitting corrosion in water containing chlorides • Not subject to stress corrosion cracking, or intergranular corrosion when welded properly • Much better working characteristics – much easier to cut, bend and fold • Better thermal properties, giving less distortion in welding and requiring less tack welding • Lower density, covering 3.5% more area at the same weight |

Grade 445M2 has excellent punchability, bendability and weldability, making it easy to fabricate. It fabricates like carbon steel, without the strong work hardening of austenitic stainless steels like grade 316, which make them hard to cut and bend. Typical applications are anywhere that 316 marine grade stainless is used now. Grade 445M2 is ideal for kitchen benchwork, food preparation equipment, street furniture, heat exchangers, solar panels, roofing, walling and rainwater goods. In fact, anywhere that 316 is used for its corrosion resistance, 445M2 will perform better. 445M2 stainless steel is available as coil and sheet 1219 mm wide and 0.55, 0.7, 0.9, 1.2, 1.5, 1.6, 2.0, 2.5 and 3.0 mm thick – all 1219mm wide. Ask us if you need narrower material. The standard finish is 2B, ask about the non-reflective 2DR finish if you want a lower gloss level for architectural applications. Do you need 445M2 stainless steel for your next project? Get in touch via our contact form to discuss your specific requirements or call us on 02 9827 0790. |

| ||

Fabrication | ||

445M2 is easier to work with than austenitic stainless steels such as 316: the much lower rate of work hardening gives lower forming loads, and less springback. Grade 445M2 also behaves like carbon steel in cutting operations: it gives cleaner cuts, with less distortion, and much better tool life. These advantages have been crucial for the introduction of the grade to uses like roll formed roofing and cladding and expanded metal. It is also very useful for perforating into acoustic screens etc. The New Marine Grade Stainless Steel | ||

Weldability• 445M2 can be spot or seam resistance welded. Post heat treatment of the weld is not required. • 445M2 can be TIG or MIG welded. Pre or post heating or post weld heat treatment are not required. • 445M2 can be welded without filler metal. If filler metal is required, use 316L(Si) • 445M2 can be laser or plasma cut. After welding, the full corrosion resistance of the surface can be restored by removing any scale and oxide colours mechanically or chemically. Best corrosion resistance is achieved by pickling to ensure the removal of the low chromium layer formed under the high-temperature oxide during welding. Pickling pastes are available: in common with other highly corrosion resistant grades, 445M2 should usually be pickled for a time towards the top of the recommended period. | ||

Corrosion Resistance | ||||

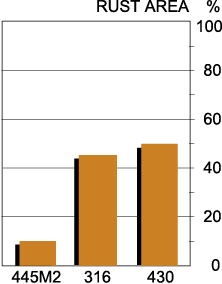

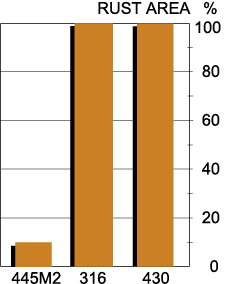

The world-class Japanese steel mill, NISSHIN STAINLESS STEEL has formulated this grade carefully for good properties. The extra high chromium content (22%) and added molybdenum give excellent corrosion resistance. Then there’s a well-balanced addition of small amounts of both niobium and titanium to protect the properties when the steel is welded. And all heats of 445M2 are made with very low carbon content, well below the 0.03% carbon in the special low carbon 316L used for better-welded corrosion resistance. Corrosion Scientists use PREN (Pitting Resistance Equivalent Number) to compare the resistance of different grades to localised corrosion. With a typical PREN of 26, 445M2 has better corrosion resistance than 316 with a typical PREN of 25. Rust area after two years of exposure to marine atmospheres. 316 and 304 – 2B finish. 445M2 – 2DR finish. | ||||

|

| |||

| 5 km from sheltered ocean in an industrial area at the same latitude as Sydney | ||||

|

| |||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

Workability, durability, affordability | ||||

Lockers Group. Stainless Steel Security Screens AWM worked closely with the Lockers Group to develop expanded metal mesh for security doors and windows. The existing aluminium mesh gave excellent performance inland but had limited life in the aggressive conditions near the ocean. Lockers turned to stainless steel for a solution. But flat panels of mesh were hard to produce in 316, and the tools wore rapidly, causing high downtime for tool sharpening. 445M2 solved both problems and had even better corrosion resistance to cope with the arduous conditions near the ocean. Manufacturing Director Peter Lowther says “the strong sales growth of the marine grade stainless steel security mesh testifies to the suitability of 445M2 for this application. We provide a superior product for our customers, which uses the strength of the 445M2 to give an unobstructed view from comfort and security. The boys in the tool room love it – they don’t see the tools as often as they used to!” | ||||

|  | |||

| Traditional Security Screen | 445M2 Stainless Steel Security Screen | |||

Stramit Building Supplies Glen Roberts, Market Development Manager at Stramit, says “We supply walling, roofing, gutters and downpipes in 445M2. We haven’t had a problem with tea staining, and we have minimal setup time when we run 445M2 on roll formers set up for carbon steel – cleanliness is the key. We always clean the machines down well to remove any carbon steel contamination. We have even had success perforating 445M2 for acoustic screens. When combined with enclosed 50mm acoustic glasswool, Stramit® Acoustic Panels are an effective noise-reduction solution for gymnasiums, factories, public buildings and offices. The wall and ceiling panels add value by providing a “three-in-one” solution that acts as cladding, sound barrier and thermal insulation simultaneously.” | ||

|

|