Nickel Alloys Inco Alloy C-276

Inco Alloy C-276 UNS-N10276 | |

Inco alloy C-276 is a nickel, chromium, molybdenum, tungsten alloy designed for outstanding corrosion resistance in a wide range of severe environments. This alloy is non magnetic, single phase and has good strength and ductility. Chemical Composition of Nickel Alloy C-276ASTM B574 – Rod

Equivalent Specifications

ASTM Product Specifications

Specified Minimum Mechanical PropertiesASTM B574 – Rod

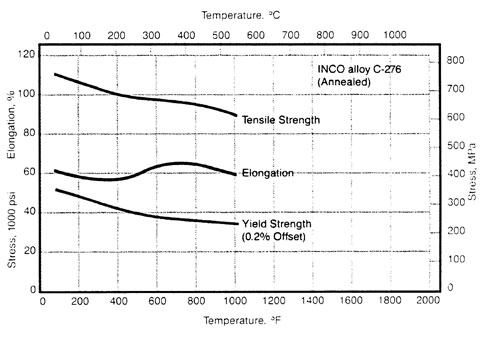

Availability of Nickel Alloy C-276Austral Wright Metals can supply this C276 alloy as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, welding fittings, forgings and forging stock. DescriptionInco C-276 is a nickel chromium molybdenum tungsten alloy designed for corrosion resistance in a wide variety of severe environments. The alloy has good strength and ductility, and can be used at elevated temperatures. It can not be hardened by heat treatment but will harden by cold work. In the annealed condition it is strengthened by solid solution hardening with nickel, chromium, molybdenum and tungsten. C-276 has outstanding corrosion resistance in sulphuric and hydrochloric acids, & the nickel level gives near immunity to stress corrosion cracking. Typical Applications for Nickel Alloy C-276Used in severe environments in chemical processing, pollution control, pulp and paper manufacture, treatment of industrial wastes and municipal waste. Applications in chemical processing include heat exchangers, reaction vessels, evaporators and process piping. In air pollution control: stack liners, ducts, dampers, scrubbers, stack gas reheaters, fans and fan housings. In sour gas recovery Inco C-276 delivers a high level of performance in various down hole and surface components, including tubing, coupling and subsurface valves. Physical Properties of Nickel Alloy C-276

Corrosion Resistance of Nickel Alloy C-276Outstanding corrosion resistance is the major attribute of C-276. The alloy resists general corrosion, stress corrosion cracking, pitting and crevice corrosion in a wide range of aggressive environments. It has very low carbon content, and in most media can be used as welded without loss of corrosion resistance. C-276 has exceptional resistance to many of the most severe media in chemical processing. Including highly oxidising neutral and acid chlorides, solvents, formic and acetic acids, acetic anhydride, wet chlorine gas, hypochlorites and chlorine solutions. In flue gas desulphurisation applications C-276 outperforms many other alloys Maximum pitting or crevice attack, mm in FGD scrubber slurry(6 months at 52°C, pH 5.5, 5000 ppm chlorides)

FabricationInco C-276 is readily fabricated by standard methods. Work hardening in cold forming may require intermediate annealing. Heavy forces are required for both hot and cold forming due to the high strength of C-276. MachinabilityInco C-276 is classed as a “D-2” alloy as it is difficult to machine. Heavy machines, sharp tools, slow speeds and deep, continuous cuts to remove the work hardened layer are needed. Heat TreatmentInco C-276 is annealed at 1150 – 1175oC and water quenched. Please consult Austral Wright Metals for specific advice. WeldabilityInco C-276 is readily welded by GMAW (MIG), GTAW (TIG), SMAW (manual) and SAW processes. Preheat, post heat and post weld heat treatment are not needed. Clean the parent material to avoid contamination of the weld pool. Welding Consumables

|