Grade 316 Stainless Steel

|

Product Data Sheet - 316 Stainless Steel |

Grades 316, 316H UNS-S31600, S31603, S31609 |

What is 316 Stainless Steel?

Grade 316 Stainless Steel is the second most commonly used stainless steel, behind 304 stainless steel. It is an austenitic, corrosion-resistant steel with excellent strength, toughness, fabrication characteristics and weldability. The low carbon version, 316L, may be required for full corrosion resistance when thicker sections are welded. The 316H version has a guaranteed minimum carbon content, which ensures good strength at high temperatures.

316 is a member of the 18/8 chromium nickel family of austenitic stainless steels, with an addition of 2% molybdenum for improved corrosion resistance, particularly to localised corrosion in chloride containing environments. The very tough and ductile austenitic structure gives grade 316 excellent formability and fabrication characteristics.

In most applications the steel is used where its corrosion resistance gives long lasting service life and appearance. The ease of cleaning and of maintaining a hygienic surface on the steel make it excellent for many purposes.

The low carbon version, 316L, may be required for full corrosion resistance when sections thicker than about 5 mm are welded. The version with guaranteed high carbon, 316H, may be required for elevated temperature service, such as pressure vessels.

Availability

Austral Wright Metals can supply this grade as plate, coil, sheet, strip, round, hexagon, flat bar, angles, tube, pipe and welding consumables.

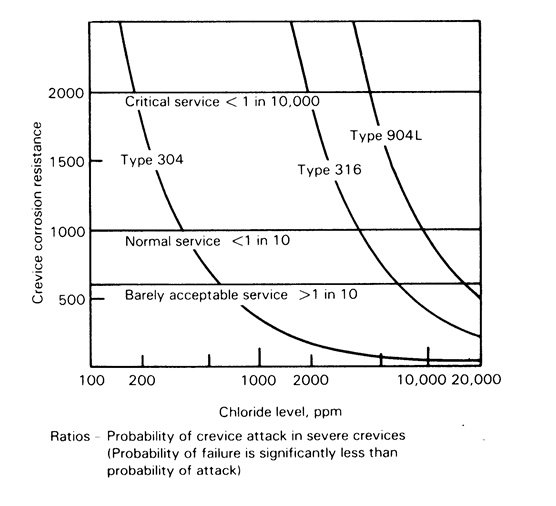

Typical Applications for 316 Stainless Steel Brewing and dairy equipment, evaporators, drums, barrels, heat exchangers, chemical and food processing, water treatment plant, chemical processing equipment, architectural and boat fittings exposed to marine and polluted atmospheres are typical uses for grade 316 stainless steel. Corrosion Resistance316 stainless steel has excellent corrosion resistance in many environments. It gives good service in atmospheric conditions, resisting most environments and is often used in marine conditions, or where industrial pollution is heavy. Best appearance is maintained where the design allows even rain washing of the surface, or where dirt deposits are occasionally washed off the steel. Grade 316 also has given excellent service in potable water. Pitting and crevice corrosion may occur in waters with higher chloride content, and 2000 ppm is accepted as the upper limit. The higher molybdenum content of 316 make it significantly more corrosion resistant than grade 304. 316 stainless steel can be used with seawater, provided precautions are taken to avoid crevice corrosion developing under sediments, precipitation and biofouling, and at designed-in crevices. Grade 316, and grade 304, may suffer stress corrosion cracking in solutions containing chloride ions at temperatures over about 60°C. Stress corrosion cracking should be considered for all corrosion services where the corrosive liquid may contain chloride. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Carbon | Silicon | Manganese | Phosphorus | Sulphur | Nickel | Chromium | Molybdenum | Nitrogen | ||

| 316 | Specification (max) | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 10.00 - 14.00 | 16.00 - 18.00 | 2.00 - 3.00 | 0.10 |

(typical) | 0.037 | 0.45 | 1.60 | 0.032 | 0.007 | 10.72 | 16.95 | 2.12 | 0.031 | |

| 316L | Specification (max) | 0.03 | 0.75 | 2.00 | 0.045 | 0.030 | 10.00 - 14.00 | 16.00 - 18.00 | 2.00 - 3.00 | 0.10 |

(typical) | 0.020 | 0.49 | 1.54 | 0.030 | 0.004 | 10.70 | 17.00 | 2.12 | 0.037 | |

| 316H | Specification (max) | 0.04 - 0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 10.00 - 14.00 | 16.00 - 18.00 | 2.00 - 3.00 | - |

(typical) | 0.050 | 0.37 | 1.67 | 0.033 | 0.009 | 10.69 | 16.90 | 2.13 | 0.025 | |

Mechanical Properties

(AS1449 / ASTM A240 - Flat Products)

0.2% Proof Stress | Tensile Strength | Elongation | Hardness | ||

MPa | MPa | % | HB (max) | ||

| 316 | Specification (min) | >= 205 | >= 520 | >= 40 | <= 217 |

typical values | 270 | 600 | 55 | 145 | |

| 304L | Specification (min) | >= 170 | >= 485 | >= 40 | <= 217 |

typical values | 270 | 600 | 55 | 145 | |

| 304H | Specification (min) | >= 205 | >= 515 | >= 40 | <= 217 |

typical values | 270 | 600 | 55 | 145 | |

Finishes

No1 (hot rolled, annealed and pickled), 2D (cold rolled), 2B (cold rolled, skin passed), N4 (polished).

Flat products are available surface protected with white polyethylene (PE) film. Protection with blue poly vinyl chloride (PVC) for deep drawing or black PVC (for heavy forming) is also available.

Physical Properties

(Typical, annealed)

| Property | At | Value | unit |

|---|---|---|---|

Density | 7,900 | kg/m³ | |

Melting Range | 1375 - 1400 | °C | |

Modulus of Elasticity | 20°C | 193 | GPa |

Shear Modulus | 20°C | 77 | GPa |

Poisson's Ratio | 20°C | 0.30 | |

Thermal Conductivity | 100°C | 16.2 | W / m. °C |

Electrical Resistivity | 25°C | 0.74 | micro-ohm . m |

Electrical Conductivity | 25°C | 1.25 | % IACS |

Specific Heat | 500 | J/kg. °C | |

Relative Magnetic Permeability | 1.02 | ||

Coefficient of Expansion | 0 - 100°C | 15.9 | /°C |

| 0 - 315°C | 16.2 | /°C | |

| 0 - 540°C | 17.5 | /°C |

The technical advice and recommendations made in this Product Data Sheet should not be relied or acted upon without conducting your own further investigations, including corrosion exposure tests where needed. Please consult current editions of standards for design properties. Austral Wright Metals assumes no liability in connection with the information in this Product Data Sheet. Austral Wright Metals supplies a comprehensive range of stainless steels, copper alloys, nickel alloys and other high performance metals for challenging service conditions. Our engineers and metallurgists will be pleased to provide further data and applications advice. |