Brass: Composition, Properties & Uses – Austral Wright Metals

Application Data Sheet - Copper Alloys

Brasses

The use of brass and copper dates back centuries, and today is used in some of the latest technologies and applications while still being used is more traditional applications such as musical instruments, brass eyelets, ornamental articles and tap and door hardware.

Find out how fast we could deliver to your facility, what prices we can offer or let us help you choose the right product for you.

Application Data Sheet - Copper Alloys

What Is Brass Made Of?

Brass is an alloy made from a combination of copper and zinc to produce materials with a wide range of engineering uses. Brass composition gives the metal a melting point suitable for many applications, including suitable for joining using the brazing technique. The melting point of brass is lower than copper at around 920~970 degrees Celsius depending on the amount of Zn addition. Brass melting point is lower than that of copper because of the added Zn. Brass alloys can varying in Zn composition from as little as 5% (more commonly referred to as Gilding Metals) to over 40% as used in the machining brasses. An uncommonly used term is brass bronze, where some additions of tin are used.

What is brass used for

Brass composition and the addition of zinc to copper raises the strength and gives a range of characteristics, which makes the brasses are a very versatile range of materials. They are used for their strength, corrosion resistance, appearance and colour, and ease of working and joining. The single phase alpha brasses, containing up to about 37% Zn, are very ductile and easy to cold work, weld and braze. The dual phase alpha-beta brasses are usually hot worked.

Is there more than one brass composition?

There are many brasses with different compositions and characteristics tailored for specific applications by the level of addition of zinc. The lower levels of Zn addition are often called Guilding Metal or Red Brass. While the higher levels of Zn are alloys such as Cartridge Brass, Free Machining Brass, Naval Brass. These later brasses also have the addition of other elements. The addition of lead to brass has been used for many years to aide the machinability of the material by inducing chip break points. As the risk and dangers of lead have been realised it have more recently been replaced with elements such as silicon and bismuth to achieve similar machining characteristic. These are now know as low lead or lead free brasses.

Can other elements be added?

Yes, minor amounts of other alloying elements may also be added to copper and brass. Commons examples are lead for machine-ability as mentioned above, but also arsenic for corrosion resistance to dezincification, tin for strength and corrosion.

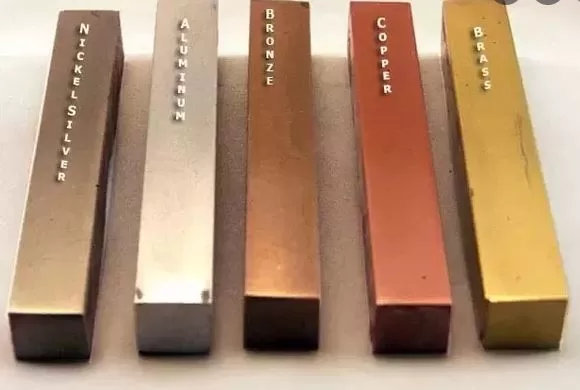

Brass Colour

As the zinc content is increased, the colour changes. The low Zn alloys can often resemble copper in colour, while the high zinc alloys appear golden or yellow.

Chemical Composition

AS2738.2 -1984

Other specifications approximately equivalent

| UNS No | AS No | Common Name | BSI No | ISO No | JIS No | Copper % | Zinc % | Lead % | Others % |

| C21000 | 210 | 95/5 Gilding Metal | - | CuZn5 | C2100 | 94.0-96.0 | ~ 5 | <0.03 | |

| C22000 | 220 | 90/10 Gilding Metal | CZ101 | CuZn10 | C2200 | 89.0-91.0 | ~ 10 | < 0.05 | |

| C23000 | 230 | 85/15 Gilding Metal | CZ102 | CuZn15 | C2300 | 84.0-86.0 | ~ 15 | < 0.05 | |

| C24000 | 240 | 80/20 Gilding Metal | CZ103 | CuZn20 | C2400 | 78.5-81.5 | ~ 20 | < 0.05 | |

| C26130 | 259 | 70/30 Arsenical Brass | CZ126 | CuZn30As | ~C4430 | 69.0-71.0 | ~ 30 | < 0.07 | Arsenic 0.02-0.06 |

| C26000 | 260 | 70/30 Brass | CZ106 | CuZn30 | C2600 | 68.5-71.5 | ~ 30 | < 0.05 | |

| C26800 | 268 | Yellow Brass (65/35) | CZ107 | CuZn33 | C2680 | 64.0-68.5 | ~ 33 | < 0.15 | |

| C27000 | 270 | 65/35 Wire Brass | CZ107 | CuZn35 | - | 63.0-68.5 | ~ 35 | < 0.10 | |

| C27200 | 272 | 63/37 Common Brass | CZ108 | CuZn37 | C2720 | 62.0-65.0 | ~ 37 | < 0.07 | |

| C35600 | 356 | Engraving Brass, 2% Lead | - | CuZn39Pb2 | C3560 | 59.0-64.5 | ~ 39 | 2.0-3.0 | |

| C37000 | 370 | Engraving Brass, 1% Lead | - | CuZn39Pb1 | ~C3710 | 59.0-62.0 | ~ 39 | 0.9-1.4 | |

| C38000 | 380 | Section Brass | CZ121 | CuZn43Pb3 | - | 55.0-60.0 | ~ 43 | 1.5-3.0 | Aluminium 0.10-0.6 |

| C38500 | 385 | Free Cutting Brass | CZ121 | CuZn39Pb3 | - | 56.0-60.0 | ~ 39 | 2.5-4.5 |

Brasses are often used for their appearance

| UNS No | Common Name | Colour |

| C11000 | ETP Copper | Soft Pink |

| C21000 | 95/5 Gilding Metal | Red Brown |

| C22000 | 90/10 Gilding Metal | Bronze Gold |

| C23000 | 85/15 Gilding Metal | Tan Gold |

| C26000 | 70/30 Brass | Green Gold |

Gilding Metal

C22000, 90/10 Gilding metal, combines a rich golden colour with the best combination of strength, ductility and corrosion resistance of the plain Cu-Zn alloys. It weathers to a rich bronze colour. It has excellent deep drawing capability, and resistance to pitting corrosion in severe weather and water environments. It is used in architectural fascias, jewellery, ornamental trim, door handles, escutcheons, marine hardware.

Yellow brasses

C26000, 70/30 Brass and C26130, Arsenical brass, have excellent ductility and strength, and are the most widely used brasses. Arsenical brass contains a small addition of arsenic, which greatly improves corrosion resistance in waters, but is otherwise effectively identical. These alloys have the distinctive bright yellow colour normally associated with brass. They have the optimum combination of strength and ductility in the Cu-Zn alloys, coupled with good corrosion resistance. C26000 is used for architecture, drawn and spun containers and shapes, electrical terminals and connectors, door handles, plumbers hardware. C26130 is used for tube and fittings in contact with water, including potable water.

C26800, Yellow brass, is the single phase alpha brass with the lowest content of copper. It is used where its deep drawing properties and lower cost give an advantage. When welded particles of beta phase may form, reducing ductility and corrosion resistance.

Brasses with other elements

C35600 and C37000, Engraving brass, are 60/40 alpha-beta brasses with different levels of lead added to give free machining characteristics. They are widely used for engraved plates and plaques, builders hardware, gears. They should not be used for acid etched work, for which the single phase alpha brasses should be used.

C38000, Section brass, is a readily extrudable leaded alpha/beta brass with a small aluminium addition, which gives a bright golden colour. The lead gives free cutting characteristics. C38000 is available as extruded rods, channels, flats and angles, which are typically used in builders hardware.

C38500, Free cutting brass, is a significantly improved form of 60/40 brass, with excellent free cutting characteristics. It is used in the mass production of brass components where maximum output and longest tool life are required, and where no further cold forming after machining is required.

Australian Product Specifications

| Specification | Product Form |

| AS1566 | Rolled flat products |

| AS1567 | Wrought rods, bars & sections |

| AS1568 | Forging stock & forgings |

| AS1569 | Seamless tubes for heat exhangers |

| AS1571 | Seamless tubes for air conditioning & refrigeration |

| AS1572 | Seamless tubes for engineering purposes |

| AS1573 | Wire for engineering purposes |

| AS1574 | Wire for electrical purposes |

Phase Diagram & Mechanical Properties

Corrosion Resistance of Brass

Brasses are resistant to corrosion in many media. Please consult Austral Wright Metals for detailed advice on your application.

Brasses are particularly susceptible to corrosion by solutions containing ammonia or amines. Alloys with more than about 15% of zinc may suffer dezincification, which leaves a weak, porous corrosion deposit of copper. Resistance to dezincification is greatly reduced by the addition of a small amount of arsenic to the alloy.

Stress corrosion cracking, particularly by ammonia and amines, is also a problem with the brasses. Alloys containing more than about 15% zinc are most susceptible. Use of the annealed temper, and annealing or stress relieving after forming, reduces susceptibility to stress corrosion cracking.

The technical advice and recommendations made in this Product Data Sheet should not be relied or acted upon without conducting your own further investigations, including corrosion exposure tests where needed. Please consult current editions of standards for design properties. Austral Wright Metals assumes no liability in connection with the information in this Product Data Sheet. Austral Wright Metals supplies a comprehensive range of stainless steels, copper alloys, nickel alloys and other high performance metals for challenging service conditions. Our engineers and metallurgists will be pleased to provide further data and applications advice.