Copper Pipe & Tubing | Austral Wright Metals

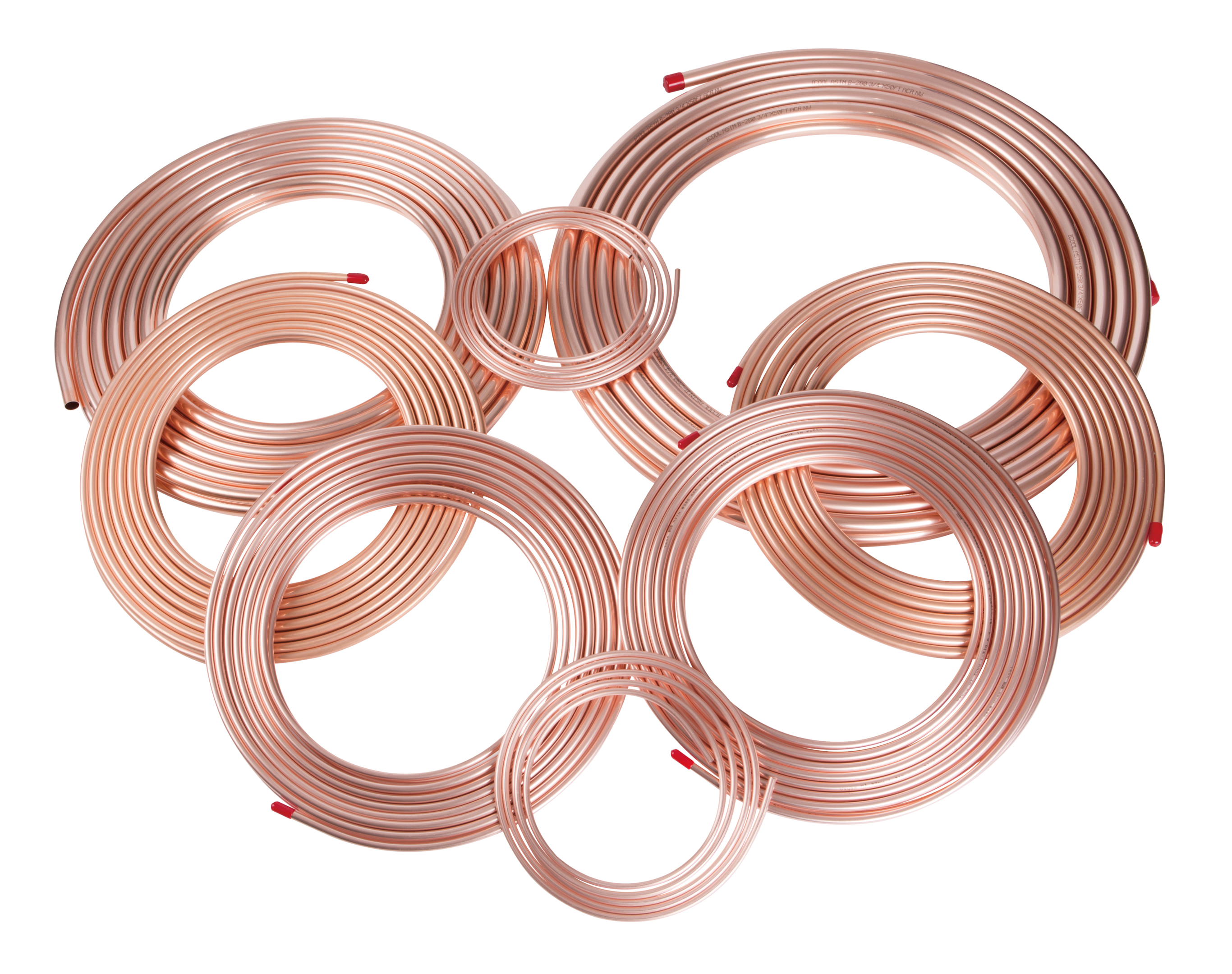

Copper Tubing & Copper Pipes for Plumbing, Gasfitting and Drainage Applications – AS1432

Austral Wright Metals copper tube & copper pipe for plumbers is manufactured to meet the requirements of Australian Standard AS1432 and carries the Watermark Certificate of approval. We also supply many manufacturing companies, so please contact us about your Layer Wound Coil (LWC) copper, non-standard sizes, refrigeration and air conditioning requirements and other designated products in copper tube and copper pipe. We have the right product for your job and delivered to your store or ready for pickup.

copper tube in straight length or coils

1/2 copper pipe and tube is classified into four different specification types based on wall thickness for a specific outside diameter. Products can be colour coded with cap as follows: Type A : Green, Copper tube Type B: Blue, Type C : Red Type D : Black. There are also several tempers available, ranging from soft, to bendable, to hard drawn. Each unique item has an individual product code in our system.

Whilst plumbing tube in Australia is still sold in inch or imperial sizes, it is hard converted into mm or metric for ordering purposes. Contact us for free delivery on large orders.

Precision Engineering for Optimal Performance

Crafted with precision and engineered to perfection, copper tube offer unparalleled performance. Their smooth interior surface minimizes friction, enhancing fluid flow efficiency and reducing energy consumption. Furthermore, copper’s natural antimicrobial properties make it an ideal choice for conveying potable water, ensuring the highest standards of hygiene and safety.

Sustainable by Nature

In an era where sustainability reigns supreme, copper tubes shine as a beacon of eco-friendliness. With a lifecycle that spans generations, copper is infinitely recyclable without compromising its quality. By choosing copper tubes, you’re not just investing in superior functionality; you’re also making a conscientious choice for the planet.

Whether it’s for plumbing, HVAC, or any other application, copper tube offer unparalleled performance and durability. This piece highlights the myriad benefits of copper tubes, positioning them as a cornerstone of modern infrastructure and a symbol of excellence in engineering.

capped tube

Inherent Strength

Copper tube has inherent strength, providing good resistance to external damage, puncture, abrasion, vibration bumps, and has a wide operating range for pressure and vacuum. Also good corrosion resistance.

Impervious

Copper tube is impervious to oxygen, insecticide, solvents and toxins.

Non-Flammable

Copper pipe and tube is non-flammable and does not emit toxic fumes during fire.

Watermark copper tube

Full Flow Joints

Copper pipe and tube jointing does not reduce the bore of the tube, maximising flow.

U.V. Resistance

Copper tube and pipe does not degrade from direct sunlight or become brittle with age.

Pancake coils

Also available in small pancake annealed coils suitable for air-conditioning applications.

copper pancake coils

Resistance Rodent Attach

Copper pipe and tube is not prone to damage due to rodent attack.

Multi Applications

Copper pipe sizes, copper pipe fittings and tube is made to universal sizes, not a unique brand size.

Stability

Copper pipe and tube does not creep with age and has 7 to 15 times less linear expansion than other materials with heat, and continues to perform at high temperatures.

Healthier and Non-tainting

Copper pipe and tube does not adversely affect the taste of water and can reduce the number of harmful micro-organisms. As seen in the well-publicised reports on the anti-microbial properties of copper.

Copper fittings

There is a wide range of 1/2 copper pipe plumbing fittings and methods for installation, such as silver solder, push fit and press fittings. Again these items are typically spoken in inches but ordered in metric sizes.

copper elbows and tee used in plumbing fittings

Recyclable

Copper pipe and tube is a valuable recyclable material.

AS1432 Copper Tubing & Copper Tubes for Plumbing, Gasfitting and Drainage Applications

TYPE A – Straight Lengths

| AWM Item Number | Nominal Size | Outside Diameter mm | Wall Thickness mm | Imperial Equivalent ODand swg | Temper | Length m | Nominal Weightkg/length | Safe Working Pressure kPa(up to 50C) |

| 70001604 | A6 | 6.35 | 0.91 | 1/4” x 20 | Hard | 6 | 0.83 | 11,320 |

| 70001603 | A8 | 7.94 | 0.91 | 5/16” x 20 | Hard | 6 | 1.08 | 8,810 |

| 70001602 | A10 | 9.52 | 1.02 | 3/8” x 19 | Hard | 6 | 1.46 | 8,350 |

| 70001018 | A15 | 12.70 | 1.02 | 1/2” x 19 | BQ | 6 | 2.01 | 6,100 |

| 70001605 | A18 | 15.88 | 1.22 | 5/8” x 18 | BQ | 6 | 3.01 | 5,750 |

| 70001606 | A20 | 19.05 | 1.42 | 3/4” x 17 | BQ | 6 | 4.22 | 5,560 |

| 70001607 | A25 | 25.40 | 1.63 | 1” x 16 | Hard | 6 | 6.53 | 4,750 |

| 70001608 | A32 | 31.75 | 1.63 | 1 1/4” x 16 | Hard | 6 | 8.27 | 3,750 |

| 70001609 | A40 | 38.10 | 1.63 | 1 1/2” x 16 | Hard | 6 | 10.02 | 3,100 |

| 70001610 | A50 | 50.80 | 1.63 | 2” x 16 | Hard | 6 | 13.50 | 2,310 |

| 70001611 | A65 | 63.50 | 1.63 | 2 1/2” x 16 | Hard | 6 | 16.99 | 1,840 |

| 70001612 | A80 | 76.20 | 2.03 | 3”x 14 | Hard | 6 | 25.37 | 1,900 |

| 70001613 | A90 | 88.90 | 2.03 | 3 1/2” x 14 | Hard | 6 | 29.71 | 1,630 |

| 70001614 | A100 | 101.60 | 2.03 | 4” x 14 | Hard | 6 | 34.05 | 1,500 |

| 70001615 | A125 | 127.00 | 2.03 | 5” x 14 | Hard | 6 | 42.74 | 1,200 |

| 70001616 | A150 | 152.40 | 2.64 | 6” x 12 | Hard | 6 | 66.61 | 1,300 |

| 70001617 | A200 | 203.20 | 2.64 | 8” x 12 | Hard | 6 | 89.21 | 910 |

TYPE B – Straight Lengths

| AWM Item Number | Nominal Size | Outside Diameter mm | Wall Thickness mm | Imperial Equivalent OD and swg | Temper | Length m | Nominal Weightkg/length | Safe Working Pressure kPa(up to 50C) |

| 70001620 | B6 | 6.35 | 0.71 | 1/4” x 22 | Hard | 6 | 0.67 | 8,560 |

| 70001619 | B8 | 7.94 | 0.71 | 5/16” x 22 | Hard | 6 | 0.86 | 6,700 |

| 70001618 | B10 | 9.52 | 0.91 | 3/8” x 20 | Hard | 6 | 1.32 | 7,220 |

| 70000845 | B15 | 12.70 | 0.91 | 1/2” x 20 | BQ | 6 | 1.81 | 5,290 |

| 70001621 | B18 | 15.88 | 1.02 | 5/8” x 19 | BQ | 6 | 2.55 | 4,810 |

| 70001293 | B20 | 19.05 | 1.02 | 3/4” x 19 | BQ | 6 | 3.10 | 3,970 |

| 70001021 | B25 | 25.40 | 1.22 | 1” x 18 | Hard | 6 | 4.97 | 3,500 |

| 70001022 | B32 | 31.75 | 1.22 | 1 1/4” x 18 | Hard | 6 | 6.28 | 2,780 |

| 70001023 | B40 | 38.10 | 1.22 | 1 1/2” x 18 | Hard | 6 | 7.58 | 2,300 |

| 70001025 | B50 | 50.80 | 1.22 | 2” x 18 | Hard | 6 | 10.19 | 1,710 |

| 70001030 | B65 | 63.50 | 1.22 | 2 1/2” x 18 | Hard | 6 | 12.80 | 1,370 |

| 70001028 | B80 | 76.20 | 1.63 | 3” x 16 | Hard | 6 | 20.48 | 1,520 |

| 70001622 | B90 | 88.90 | 1.63 | 3 1/2” x 16 | Hard | 6 | 23.97 | 1,300 |

| 70001029 | B100 | 101.60 | 1.63 | 4” x 16 | Hard | 6 | 27.45 | 1,200 |

| 70001623 | B125 | 127.00 | 1.63 | 5” x 16 | Hard | 6 | 34.43 | 960 |

| 70001557 | B150 | 152.40 | 2.03 | 6” x 14 | Hard | 6 | 51.43 | 1,000 |

| 70001558 | B200 | 203.20 | 2.03 | 8” x 14 | Hard | 6 | 68.80 | 720 |

TYPE C and D – Straight Lengths

| AWM Item Number | Nominal Size | Outside Diameter mm | Wall Thickness mm | Imperial Equivalent ODand swg | Temper | Lengthm | Nominal Weightkg/length | Safe Working Pressure kPa(up to 50C) |

| 70001625 | C10 | 9.52 | 0.71 | 3/8″ x 22 | Hard | 6 | 1.05 | 5,520 |

| 70001624 | C15 | 12.70 | 0.71 | 1/2″ x 22 | BQ | 6 | 1.43 | 4,070 |

| 70001626 | C18 | 15.88 | 0.91 | 5/8″ x 20 | BQ | 6 | 2.30 | 4,180 |

| 70001627 | C20 | 19.05 | 0.91 | 3/4″ x 20 | BQ | 6 | 2.78 | 3,450 |

| 70001628 | C25 | 25.40 | 0.91 | 1″ x 20 | Hard | 6 | 3.75 | 2,560 |

| 70001629 | D32 | 31.75 | 0.91 | 1 1/4″ x 20 | Hard | 6 | 4.73 | 2,040 |

| 70001367 | D40 | 38.10 | 0.91 | 1 1/2″ x 20 | Hard | 6 | 5.70 | 1,690 |

| 70001630 | D50 | 50.80 | 0.91 | 2″ x 20 | Hard | 6 | 7.65 | 1,260 |

| 70001631 | D65 | 63.50 | 0.91 | 2 1/2″ x 20 | Hard | 6 | 9.60 | 1,010 |

| 70001632 | D80 | 76.20 | 1.22 | 3″ x 18 | Hard | 6 | 15.41 | 1,130 |

| 70001633 | D90 | 88.90 | 1.22 | 3 1/2″ x 18 | Hard | 6 | 18.02 | 970 |

| 70001634 | D100 | 101.60 | 1.22 | 4″ x 18 | Hard | 6 | 20.63 | 890 |

| 70001635 | D125 | 127.00 | 1.42 | 5″ x 17 | Hard | 6 | 30.04 | 830 |

| 70001636 | D150 | 152.40 | 1.63 | 6″ x 16 | Hard | 6 | 41.40 | 800 |

COILS

| AWM Item Number | Nominal Size | Outside Diameter mm | Wall Thickness mm | Imperial Equivalent OD and swg | Temper | Length m | Nominal Weightkg/length | Quantity Per Box |

| 70001448 | A6 | 6.35 | 0.91 | 1/4″ x 20 | Annealed | 30 | 4.17 | 12 |

| 70001449 | A8 | 7.94 | 0.91 | 5/16″ x 20 | Annealed | 30 | 5.39 | 9 |

| 70001289 | A15 | 12.70 | 1.02 | 1/2″ x 19 | Annealed | 18 | 6.02 | 6 |

| 70001639 | A20 | 19.05 | 1.42 | 3/4″ x 17 | Annealed | 18 | 12.65 | 4 |

| 70001450 | B10 | 9.52 | 0.91 | 3/8″ x 20 | Annealed | 18 | 3.96 | 8 |

| 70000809 | B15 | 12.70 | 0.91 | 1/2″ x 20 | Annealed | 18 | 5.42 | 6 |

| 70001641 | B18 | 15.88 | 1.02 | 5/8″ x 19 | Annealed | 18 | 7.66 | 5 |

| 70001535 | B20 | 19.05 | 1.02 | 3/4″ x 19 | Annealed | 18 | 9.30 | 4 |

| 70001642 | B25 | 25.40 | 1.22 | 1″ x 18 | Annealed | 18 | 14.91 | 1 |

| 70001643 | C18 | 15.88 | 0.91 | 5/8″ x 20 | Annealed | 18 | 6.89 | 5 |

| 70001644 | C20 | 19.05 | 0.91 | 3/4″ x 20 | Annealed | 18 | 8.34 | 4 |

COPPER TUBING & COPPER TUBE PROPERTIES

Phosphorus Deoxidised Copper High Residual Phosphorus

ALLOY C12200

| CHEMICAL COMPOSTION | |||

| Copper: | 99.90% minimum | ||

| Phosphorus: | 0.015%-0.040% | ||

| TUBE SPECIFICATIONS | |||

| Recommended: | AS 1432 | ||

| Related: | AS 1569, 1571, 1572, EN 1057, ASTM B75, B88, JIS H3300, NZS 3501 | ||

| PHYSICAL PROPERTIES | |||

| Melting Point: | 1083ºC | ||

| Density: | 8.94 x 103 kg/m3 at 20ºC | ||

| Thermal Expansion Coefficient (20-100ºC): | 16.8 x 10-6 perºK | ||

| Thermal Conductivity (20-100ºC): | 305-320 W/(m.K) | ||

| Specific Heat Capacity: | 385 J/kg ºK | ||

| Electrical Conductivity (annealed): | 75-90% I.A.C.S. | ||

| Electrical Resistivity (annealed): | 0.0192-0.0230 microhm m at 20ºC | ||

| Modulus of Elasticity: | 117 GPa | ||

| Modulus Rigidity: | 44 GPa | ||

| JOINTING PROPERTIES | FABRICATION PROPERTIES | ||

| Soldering: | Excellent | Cold Work: | Excellent |

| Brazing: | Excellent | Hot Work: | Excellent |

| Welding: | Hot Work Temp: | 750ºC-875ºC | |

| Oxy-Acetylene: | Good | Annealing Range: | 450ºC-600ºC |

| Gas Shield Arc MIG/TIG: | Good | ||

| Coated Metal Arc: | Not recommended | ||

| Resistance Spot & Seam: | Not recommended | ||

| Resistance Butt: | Not recommended | ||

| SUITABLIITY FOR SURFACE FINISHING BY | |||

| Polishing: | Excellent | Machining: | Machinability Rating 20% |

| Plating: | Excellent | ||

| MECHANICAL PROPERTIES | |||

| Tube Temper | Annealed | Bendable | Hard Drawn |

| Hardness (HV5) – Specification | 70 max | 80-100 | 100 min |

| Yield (0.2% Proof) (MPa) – Typical | 70 | 220 | 350 |

| Ultimate tensile (MPa) – Typical | 220 | 280 | 380 |

| Elongation (% on 50mm) – Typical | 55 | 20 | 5 |