Copper Strip & Bar – Round, Square and Flat products (including busbar) from Austral Wright MetalsAustral Wright Metals has a history of over 75 years as one of the industry's leading sellers of copper bar products. The superior qualities of copper and copper alloy make them the ideal products in a vast range of commercial, industrial and domestic applications.

In addition to its well known traditional properties – electrical and thermal conductivity, malleability and resistance to corrosion – copper is far more versatile in combining with other metals to give performance characteristics needed to satisfy today's increasingly complex demands. To meet the exact specifications of our customers, Austral Wright Metals sources, stocks and supplies products from leading copper and brass mills around the world. Customers can request products to be produced to their individual specifications, or select from Austral Wright Metals' extensive stocks of copper and copper bar products. To download PDFs click here.

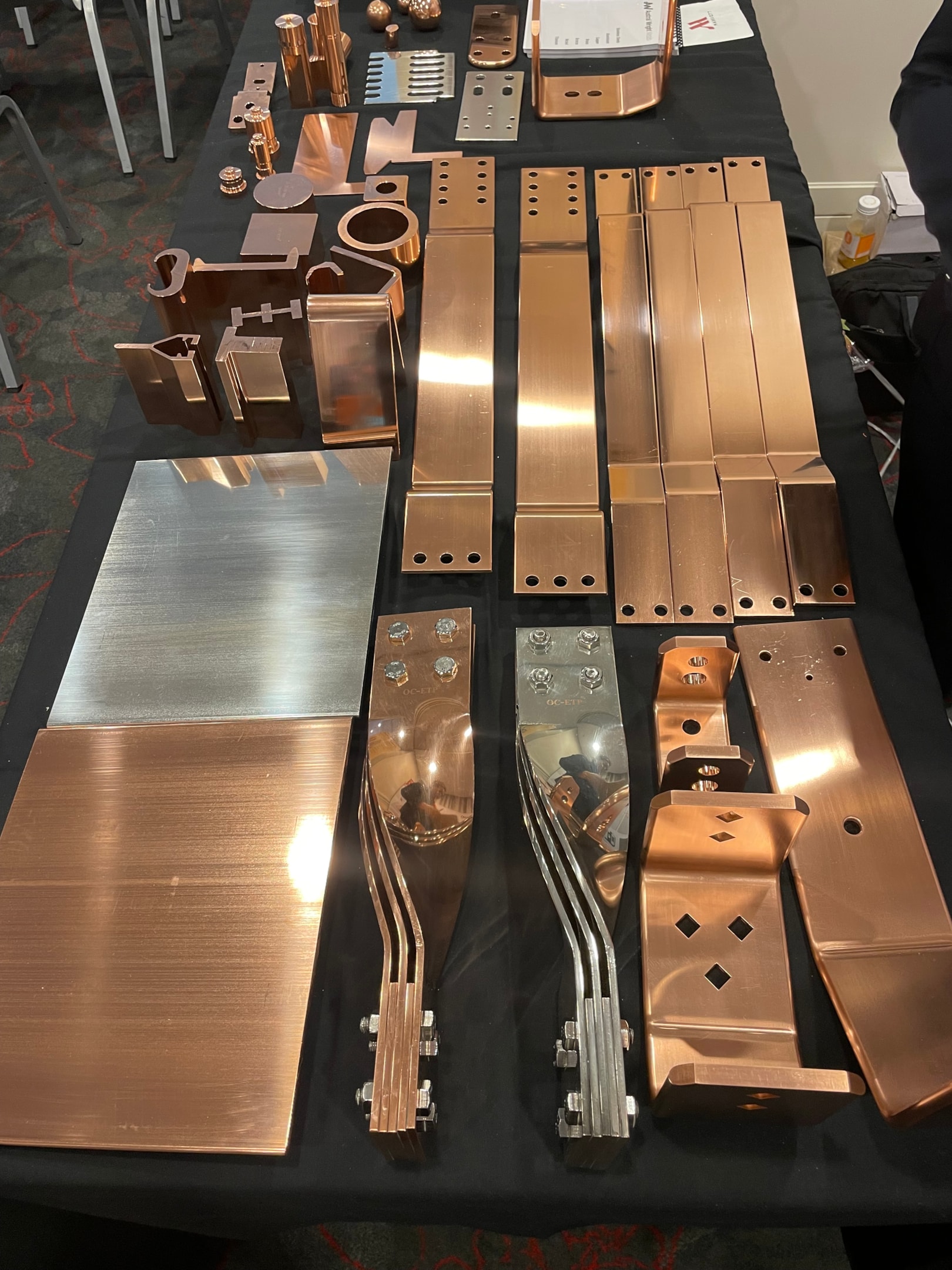

What are copper flat bars and strip used for?Copper bars have a wide range of uses due to the unique properties of copper, including its excellent electrical and thermal conductivity, corrosion resistance, and malleability. Here are some common applications of copper bars and copper strip: - Electrical Wiring: Copper bars are frequently used in electrical wiring and power distribution systems. The high conductivity of copper ensures efficient transmission of electricity, which minimizes energy loss.

- Grounding and Earthing Systems: Copper bars are used in grounding and earthing systems to provide a low-resistance path for electrical currents to safely dissipate into the ground, preventing electrical accidents and lightning strikes.

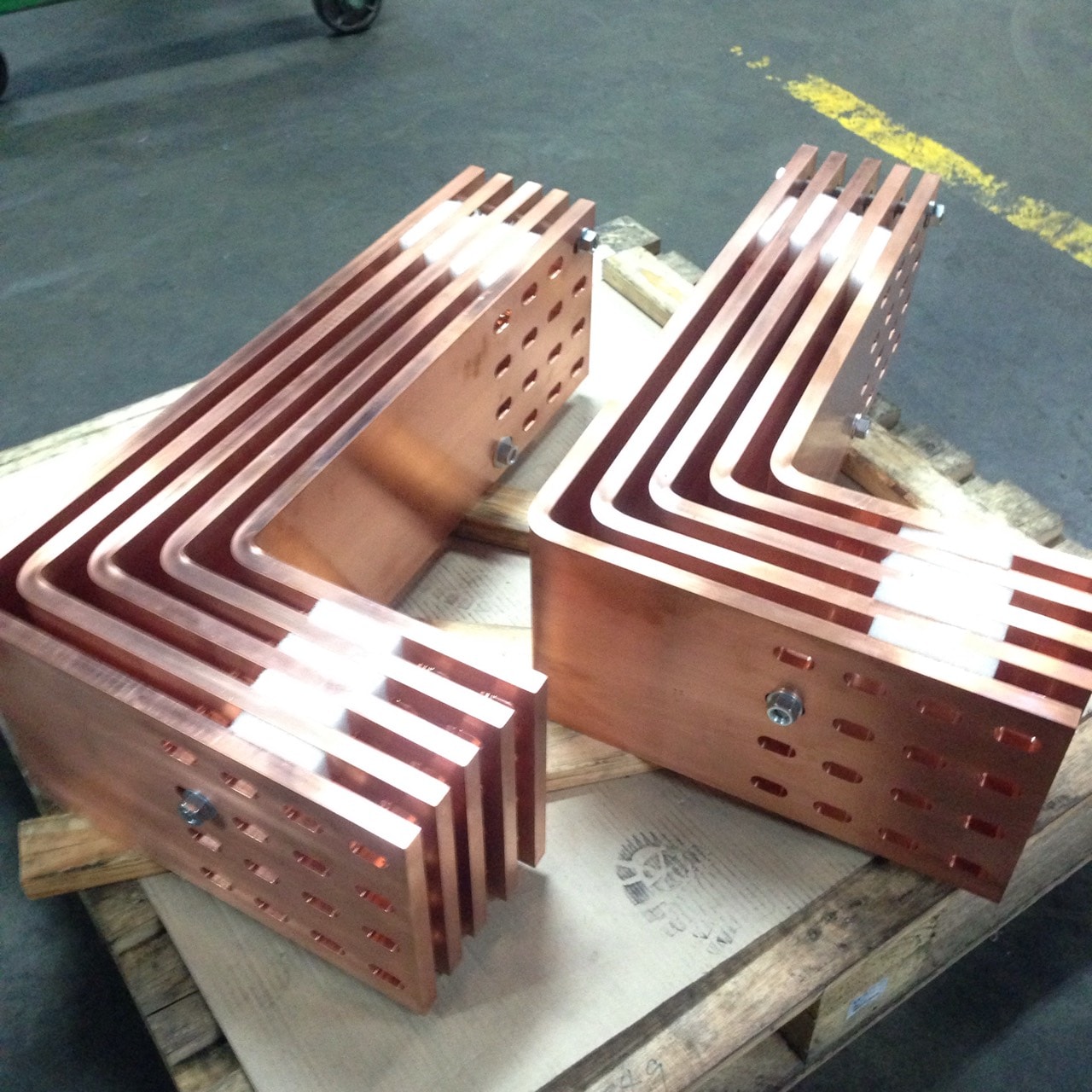

- Electrical Busbars: Copper busbars are essential components in electrical switchgear, circuit breakers, and distribution panels. They facilitate the distribution of electrical power within these systems.

- Electrical Connectors: Copper bars are used to create reliable electrical connections, including wire splicing, terminal blocks, and electrical connectors.

- Heat Exchangers: Copper's excellent thermal conductivity makes it suitable for heat exchangers used in HVAC systems, refrigeration units, and industrial processes.

- Plumbing and Piping: Copper bars are utilized in plumbing and piping systems for both residential and commercial applications. Copper's corrosion resistance ensures the durability of water pipes and fittings.

- Roofing and Cladding: Copper is often used for roofing and cladding due to its corrosion resistance and aesthetic appeal. Over time, copper develops a protective patina that gives it a distinctive greenish-blue color.

- Sculptures and Artwork: Artists and sculptors use copper bars and sheets for their creative projects due to its malleability and the unique patina it develops.

- Antimicrobial Surfaces: Copper's natural antimicrobial properties make it suitable for touch surfaces in healthcare settings, such as door handles and handrails, to help reduce the spread of bacteria and viruses.

- Electrical Motors and Transformers: Copper bars are essential components in electrical motors and transformers, where they carry and distribute electrical currents.

- Automotive Radiators: Copper and copper-alloy tubes and fins are used in automotive radiators for their excellent heat transfer properties.

- Jewellery: Copper is sometimes used in jewelry making, either in its pure form or as part of an alloy. It can be polished to a bright finish or left to develop a natural patina for aesthetic appeal.

These are just a few examples of the many applications of copper bars. The versatility and useful properties of copper make it a valuable in various industries and everyday products.

Why choose Austral Wright Metals?Austral Wright Metals specialises in the supply of high-quality metals and related products. If you're considering why a customer might choose Austral Wright Metals, here are reasons to search us: - Wide Range of Metals: Austral Wright Metals is a stockist and re seller that offers a diverse range of items, including stainless steel, copper, brass, bronze, aluminum, titanium, and specialty alloys. This variety allows customers to find the specific material that suits their needs.

- Quality Assurance: Our emphasis on commitment to quality assurance. This includes adhering to industry standards and providing products that meet or exceed expectations. Together with our ISO9001 accreditation.

- Expertise and Knowledge: Austral Wright Metals has a team of experts with in-depth knowledge and details of metals and their applications. Customers can benefit from our advice and assistance in selecting the right materials for their projects. So contact us no matter the subject and we will help you sort it out. Click on our enquiry link.

- Customisation: Our customised order services, customers may choose it for the ability to have materials cut, shaped, or fabricated to their exact specifications in partnership with our overseas suppliers.

- Reliable Supply: Austral Wright Metals consistently delivers on time and in the quantities required.

- Technical Support: Providing technical support, including data sheets, material specifications, and technical guidance, can help customers make informed decisions about their metal requirements.

- Competitive Pricing: Competitive pricing or flexible pricing structures..

- Customer Focus: Demonstrating a commitment to excellent service, clear communication, and responsive support.

- Nationwide Coverage: Austral Wright Metals has a broad distribution network across Australia.

Copper Bar - Flat| Metric (mm) | Imperial (inches) | kg/m (nominal) | Alloy C11000 Plain | Alloy C11000 Tinned | | SE | FR | Square edge (SE) | Radius Corner (RC) | Full Radius(FR) | Square edge (SE) | Radius Corner (RC) | Full Radius (FR) | | 12.7 x 3.18 | 1/2 x 1/8 | 0.36 | 0.34 | 50003940 | | | | | | | 15.88 x 3.18 | 5/8 x 1/8 | 0.45 | 0.43 | 50003942 | | | | | | | 19.05 x 3.18 | 3/4 x 1/8 | 0.54 | 0.52 | 50003928 | | | | | | | 19.05 x 4.76 | 3/4 x 3/16 | 0.81 | 0.76 | 50003944 | | | | | | | 19.05 x 6.35 | 3/4 x 1/4 | 1.08 | 1.00 | | | 50004036 | | | | | 20 x 6.3 | | 1.12 | 1.05 | | | 50003924 | | | 50003912 | | 20 x 10 | | 1.78 | 1.59 | | 50113149 | | | 50113152 | | | 25 x 6.3 | | 1.40 | 1.33 | | | 50003923 | | | 50003909 | | 25 x 10 | | 2.23 | 2.03 | | 50004026 | | | 50066094 | | | 25.4 x 3.18 | 1 x 1/8 | 0.72 | 0.70 | 50003930 | | 50003992 | | | | | 25.4 x 4.76 | 1 x 3/16 | 1.08 | 1.03 | 50003945 | | | | | | | 25.4 x 19.05 | 1 x 3/4 | 4.31 | 3.61 | 50003969 | | | | | | | 30 x 10 | | 2.67 | 2.48 | | 50004025 | | | 50004042 | | | 31.5 x 6.3 | | 1.77 | 1.69 | | | 50003925 | | | 50003981 | | 31.75 x 3.18 | 1 1/4 x 1/8 | 0.90 | 0.88 | 50003931 | | 50003973 | | | | | 31.75 x 6.35 | 1 1/4 x 1/4 | 1.79 | 1.72 | 50003957 | | | | | | | 38.1 x 3.18 | 1 1/2 x 1/8 | 1.08 | 1.06 | 50003932 | | 50097422 | | | | | 38.1 x 4.76 | 1 1/2 x 3/16 | 1.61 | 1.57 | 50003947 | | 50003967 | | | | | 38.1 x 19.05 | 1 1/2 x 3/4 | 6.46 | 5.77 | 50003896 | | | | | | | 40 x 6.3 | | 2.24 | 2.17 | | | 50003926 | | | 50004011 | | 40 x 10 | | 3.56 | 3.37 | | 50003961 | | | 50066102 | | | 50 x 6.3 | | 2.80 | 2.73 | | | 50004053 | | | 50004060 | | 50 x 10 | | 4.45 | 4.26 | | 50003966 | 50003922 | | 50004040 | | | 50.8 x 3.18 | 2 x 1/8 | 1.44 | 1.42 | 50003935 | | | | | | | 50.8 x 4.76 | 2 x 3/16 | 2.15 | 2.11 | 50003948 | | | | | | | 50.8 x 6.35 | 2 x 1/4 | 2.87 | 2.79 | 50003937 | | | 50003883 | | | | 50.8 x 12.7 | 2 x 1/2 | 5.74 | 5.43 | 50003994 | | | | | | | 60 x 6.3 | | 3.36 | 3.29 | | | 50011337 | | | | | 60 x 10 | | 5.34 | 5.15 | | 50003964 | | | 50004024 | | | 60 x 12 | | 6.41 | 6.13 | | 50003959 | | | 50003971 | | | 63 x 6.3 | | 3.53 | 3.46 | | | 50003956 | | | 50003894 | | 63.5 x 3.18 | 2 1/2 x 1/8 | 1.80 | 1.78 | 50003943 | | | | | | | 80 x 6.3 | | 4.49 | 4.41 | | | 50004047 | | | 50003892 | | 80 x 10 | | 7.12 | 6.93 | | 50004023 | 50003955 | | 50004012 | | | 100 x 6.3 | | 5.61 | 5.53 | | | 50004046 | | | 50003906 | | 100 x 10 | | 8.90 | 8.71 | | 50004049 | 50115359 | | 50117516 | 50066103 | | 101.6 x 6.35 | 4 x 1/4 | 5.74 | 5.66 | 50003983 | | | | | | | 101.6 x 12.7 | 4 x 1/2 | 11.48 | 11.18 | 50003844 | | | | | | | 101.6 x 25.4 | 4 x 1 | 22.97 | 21.73 | 50003849 | | | | | | | 120 x 10 | | 10.68 | 10.49 | | 50003835 | | | 50116699 | | | 125 x 6.3 | | 7.01 | 6.93 | | | 50004022 | | | 50003927 | | 152.4 x 6.35 | 6 x 1/4 | 8.61 | 8.54 | 50004001 | | | | | | | 152.4 x 12.7 | 6 x 1/2 | 17.23 | 16.92 | 50119892 | | | | | | | 152.4 x 25.4 | 6 x 1 | 34.45 | 33.22 | 50119893 | | | | | | | 160 x 6.3 | | 8.97 | 8.90 | | | 50004021 | | | 50003874 | | 160 x 10 | | 14.25 | 14.05 | | 50004027 | | 50003917 | | |

|

| Please Note: Other sizes available on request. Standard Length: 4000mm |

Copper Bar - Round| Metric (mm) | Imperial (inches) | kg/m (nominal) | Alloy | | C11000 High Conductivity Copper | C14700 Free Machining Copper | | 4.76 | 3/16 | 0.16 | 50003649 | | | 6.35 | 1/4 | 0.28 | 50003650 | | | 7.94 | 5/16 | 0.44 | 50003651 | | | 9.53 | 3/8 | 0.64 | 50003653 | | | 12.7 | 1/2 | 1.13 | 50003392 | 50003407 | | 15.88 | 5/8 | 1.77 | 50003393 | | | 17.46 | 11/16 | 2.14 | | 50003471 | | 19.05 | 3/4 | 2.55 | 50003395 | 50114703 | | 22.23 | 7/8 | 3.47 | 50003396 | | | 25.4 | 1 | 4.53 | 50003397 | 50003472 | | 31.75 | 1 1/4 | 7.08 | 50003508 | | | 38.1 | 1 1/2 | 10.19 | 50003510 | 50025282 | | 44.45 | 1 3/4 | 13.87 | 50003511 | | | 50.8 | 2 | 18.12 | 50003513 | | | 63.5 | 2 1/2 | 28.31 | 50003630 | |

|

| Please Note: Other sizes available on request. Standard Length: 3600mm |

Copper Square| Metric (mm) | Imperial (inches) | kg/m (nominal) | Alloy C11000 | | 50.8 | 2 x 2 | 23.00 | 50003519 |

Standard Length:3600mm Copper TubeAWS supplies Inner Groove and Smooth Bore and Layer Wound Coil| Standards | Chemical Composition % Cu | Stock / Overseas P | | C12200 or JIS C1220 | 99.90 min | 0.015-0.040 |

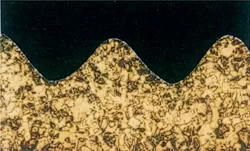

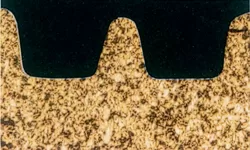

Standard Dimensions – Inner Groove Tube| Groove Type | Outer Diameter (mm) | Av Wall Thickness (mm) | No of Grooves | Helix Angle | Groove Depth (mm) | | A | 9.52 | 0.35 | 65 | 25 | 0.15 | | 9.52 | 0.41 | 65 | 25 | 0.15 | | B | 9.52 | 0.35 | 60 | 25 | 0.12 | | C | 7.94 | 0.36 | 50 | 18 | 0.2 | | 9.52 | 0.35 | 60 | 18 | 0.2 | | 9.52 | 0.36 | 60 | 18 | 0.2 | | 9.52 | 0.41 | 60 | 18 | 0.2 | | 12.7 | 0.51 | 65 | 18 | 0.25 |

For other dimensions please consult with out Sales Office. Mechanical Properties| Temper | Tensile Strength MPa | Elongation % | HR15T | Grain Size (mm) | | Light Annealed | 275 | 40 min | 65 max | 0.04 max |

Groove ShapesPDF DownloadsCopper Bar - Round, Square and Flat (including busbar) Copper Bar Brochure Copper Flat Copper Round & Square Copper Tube

|