Nickel Alloys Incoloy Alloy 825 N08825 – Austral Wright Metals

| |

Product Data Sheet Nickel Alloys | |

Incoloy 825 UNS N08825 | |

Incoloy® Alloy 825™ is a nickel iron chromium alloy with additions of molybdenum, copper and titanium, with exceptional resistance to many aggressive corrosion environments. Chemical Composition of Incoloy 825ASTM B163 – Heat Exchanger Tube

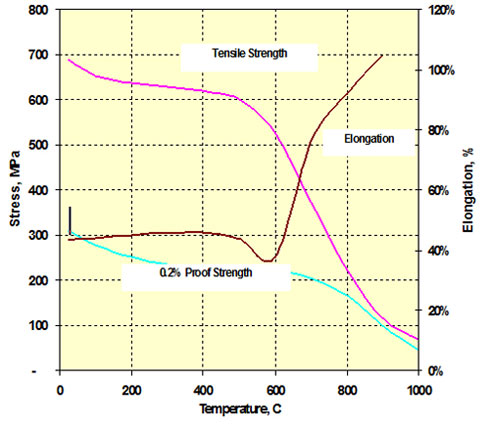

Typical Room Temperature Tensile Properties of Incoloy 825NOT FOR DESIGN. Consult the relevant material or product specification for design values.

Typical Applications for Incoloy 825Sulphuric acid piping and vessels, phosphoric acid evaporators, pickling tank heaters, pickling tanks and equipment, chemical process equipment, propellor shafts, tank trucks, calorifiers, electrostatic precipitator electrodes, hot vessels for food, water and seawater, ammonium sulphate vessels, expansion bellows, marine exhaust systems, power station ash hoppers.

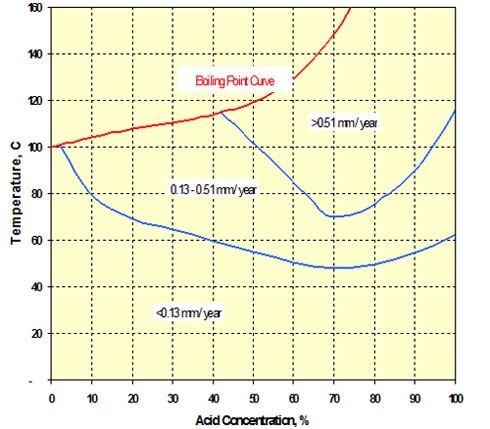

Incoloy 825 DescriptionIncoloy 825 is highly resistant to corrosion. It has a high nickel content, sufficient to resist chloride ion stress corrosion cracking, and a very stable austenite structure. The levels of molybdenum and copper enable the alloy to resist reducing agents and acids. Chromium gives resistance to oxidising conditions, such as nitric acid solutions, nitrates and oxidising salts. The alloy is titanium stabilised to resist pitting and intergranular attack after fabrication, particularly welding, which includes heating in the critical sensitisation temperature range (650°C – 760°C). Alloy 825 offers exceptional resistance to corrosion by sulphuric and phosphoric acids and is often the most cost effective alloy in sulphuric acid service. Availability of Incoloy 825Austral Wright Metals can supply this alloy as plate, sheet, strip, bar, rod, wire, tube, pipe, fittings, fasteners. Pressure VesselsIncoloy 825 is approved for pressure vessel operating temperatures up to 525°C (AS1210, AS4041), 538°C (ASME Boiler & Pressure Vessel Code, Sections I, III, VIII, IX, Cases 1936, N-188). Brittle phases may form in alloy 825 at temperatures above ~ 540°C, so it is not normally used at these temperatures, where creep-rupture properties would be design factors. Corrosion ResistanceThe outstanding property of Incoloy 825 is its corrosion resistance. In reducing & oxidising conditions, Incoloy 825 resists general corrosion, pitting & crevice corrosion, intergranular corrosion and stress corrosion cracking. It is particularly useful in sulphuric & phosphoric acids, sulphur containing flue gases, sour gas and oil wells and sea water.

Fabrication of Incoloy 825Incoloy 825 can be readily hot or cold worked. Hot working should be in the range 870 – 1180°C, finishing at 870 – 980°C. For maximum corrosion resistance hot worked parts should be stabilise annealed before use. The alloy is easier to cold form than stainless steels. MachinabilityIncoloy 825 is classed as a ‘C’ alloy, and is reasonably easy to machine. WeldabilityThe alloy is readily weldable by the normal processes (GMAW (MIG), GTAW (TIG), SMAW (manual), SAW). The joint must be clean to avoid contamination of the weld pool. Welding Consumables

Heat TreatmentIncoloy 825 is stabilise annealed at 940°C. The softest structure is obtained at 980°C. Sections heavier than sheet, strip and wire should be quenched to avoid sensitisation. Please consult Austral Wright Metals for specific advice on your application. Equivalent Specifications

Physical Properties

ASTM Product Specifications

|