Maintaining & Cleaning Stainless Steel – Austral Wright Metals

|

Application Data Sheet – Stainless Steel |

Maintaining & Cleaning Stainless Steel |

Stainless steels are often used in domestic and architectural situations for their excellent and long-lasting appearance. They are inherently corrosive-resistant materials that do not need added surface protection. With a minimum of care and attention, they will serve without the deterioration which can affect other metals and materials. However like other construction materials they are not maintenance free so in this article we show you step-by-step how to clean stainless steel.

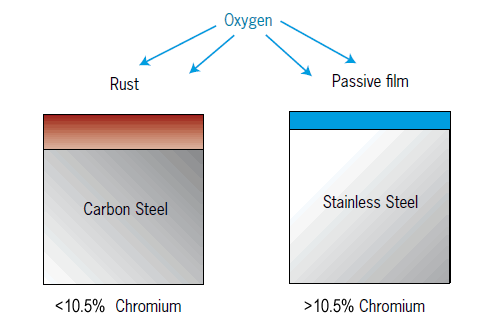

Why stainless steel has good corrosion resistanceIt is the combination of alloying elements in stainless steel that gives it a thin passive layer on stainless steel surfaces resulting in it’s superior corrosion resistance. The thin layer is formed on instantly formed in the presence of oxygen, even in water, so when the surface is scratched the passive layer continues to provide corrosion resistance to the stainless steel surface.

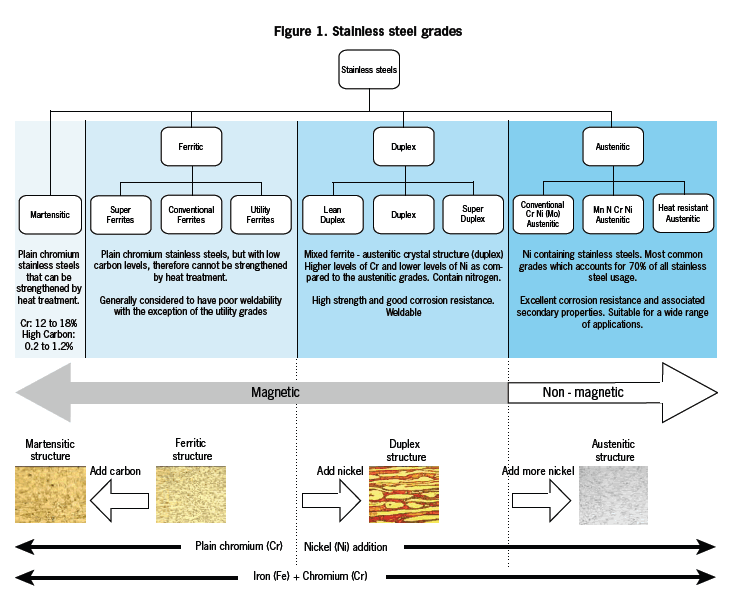

Choose the right gradeThe first essential is that the grade of stainless must be chosen to have adequate corrosion resistance for the service environment. Table 1 gives some guidance. Austral Wright Metals should be consulted in case of doubt.

Table 1: Grade Selection for Atmospheric Corrosion Resistance

M Typical of the category H Corrosion worst for the category – eg high humidity, ambient temperature, air pollution 2 – Usable if precautions are taken (use a smooth surface and wash regularly) 3 – Over specified for corrosion X – Likely to corrode excessively Traps for young players

Things to avoid and initial cleaning stepsAn adhesive plastic film during fabrication, transport and installation often protects stainless steel appliances. This provides excellent protective layer against damage and soiling, however these films will deteriorate on exposure to sunlight and UV which will make them difficult to remove if not done as soon as possible. If the stainless steel has mortar or cement splashes it can be treated with a solution containing a small amount of phosphoric acid. Rinse with water and dry. It is preferable to use deionised water for this process as it reduces the risk of water staining marks. Never allow mortar removers or diluted hydrochloric acid to be used on stainless steel. If the stainless steel has been in contact with these substances then rinse thoroughly with generous amounts of fresh water. Care should be taken to avoid stainless steel surfaces becoming contaminated with iron particles. These particles can prevent the self-healing of the stainless steel passive film and result in pitting corrosion. Therefore any contamination of iron from tools, grinding, other structures, etc should be removed immediately. However if any early stages of this iron corrosion occur, light deposits can be removed using nylon pads or a proprietary stainless steel cleaner containing phosphoric acid. If pitting has occurred, acid treatments or mechanical rectification will be needed to restore the surface. Whilst most staining, corrosion or pitting can be removed, the restoration may change the appearance of the stainless steel appliance or product. Further mechanical or chemical treatment may be needed to restore the surface to the original appearance. In some situations this may not be possible, or is it best to avoid the contamination in the first place. What not to useStainless steel cleaners that should not be used to clean stainless steel appliances, stainless steel pots, stainless steel refrigerator, stainless steel stove, or any stainless appliances include:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stain Type | Cleaning Method |

| Fingerprints | Wash with alcohol, thinners, trichlorethylene or acetone, rinse with clean cold water or glass cleaner, wipe dry with a soft cloth. |

High traffic areas of low corrosivity benefit from a light wax coating. | |

| Oil & Grease | As above, adding a washing step with soap or a mild detergent, before rinsing. |

For stubborn deposits, oven cleaners containing caustic soda (sodium hydroxide) may be tried. | |

| More Stubborn Areas | Wash with a mild abrasive cleaning agent, rubbing in the direction of the visible surface structure, rinse with clean cold water, wipe dry |

OR – Wash with 10% phosphoric acid solution, rinse with ammonia solution, then with clean cold water, wipe dry | |

OR – Rub gently with sulphamic acid powder on a damp cloth, rinse with clean cold water, wipe dry | |

| Temper colour | Wash with abrasive cleaning agent, as described above, or with a Scotchbrite sponge. |

| Rust Stains | Wet the surface with oxalic acid or 10% nitric acid, leave for 10 – 20 minutes, rinse with ammonia or sodium bicarbonate solution, rinse with clean cold water, wipe dry. This treatment may need to be repeated, depending on the severity of the rust staining. An abrasive cleaning agent may be used on some surfaces to speed rust removal. |

| Paint | Wash with paint solvent or thinners (use a soft nylon brush), rinse with clean cold water, wipe dry. |

| Scratches on a ground or brushed surface | Polish with a polishing wheel, using iron free abrasives, in the direction of the surface. Select the abrasives to match the original surface. Remove polishing residues by washing with soap or a mild detergent and water, rinse with clean cold water, wipe dry. |

Safety

Use solvents, acids etc only when necessary. Wear rubber gloves and eye protection, follow all safety regulations – ensure good ventilation, take fire precautions.

The technical advice and recommendations made in this Product Data Sheet should not be relied or acted upon without conducting your own further investigations, including corrosion exposure tests where needed. Please consult current editions of standards for design properties. Austral Wright Metals assumes no liability in connection with the information in this Product Data Sheet. Austral Wright Metals supplies a comprehensive range of stainless steels, copper alloys, nickel alloys and other high performance metals for challenging service conditions. Our engineers and metallurgists will be pleased to provide further data and applications advice.