Copper Alloys C22000 90-10 Gilding – Austral Wright Metals

|

Product Data Sheet Copper Alloys |

90/10 Gilding Metal Copper Alloy 220 UNS-C22000 |

What is Gilding MetalGilding metal is a copper based alloy containing lower levels of zinc than the Brass group of alloys. The two most common Gilding metal are C22000 or also known as Red Brass with 10% zinc and C23000 also known as Commercial bronze with 15% zinc. |

| Copper | Iron | Lead | Zinc |

| 89.0 – 91.0% | 0.05% max | 0.02% max | balance (~10%) |

Equivalent Alloy Specifications

| Specification | Designation |

| UNS | C22000 |

| BSI | CZ101 |

| ISO | Cu Zn 10 |

| JIS | C 2200 |

| SAE | CA220 |

Australian Product Specifications

| Specification | Product Form |

| AS1566 | Rolled Flat Products |

| AS1567 | Wrought Bars & Sections |

ASTM Product Specifications

| Number | Title |

| B36 | Brass Plate, Sheet, Strip and Rolled Bar |

| B130 | Commercial Bronze Strip for Bullet Jackets |

| B131 | Copper Alloy Bullet Jacket Cups |

| B134 | Brass Wire |

| B135 | Seamless Brass Tube |

| B372 | Seamless Copper and Copper Alloy Rectangular Waveguide Tube |

| B587 | Welded Brass Tube |

| B694 | Copper, Copper Alloy and Copper Clad Stainless Steel (CCS) and Copper Clad Alloy Steel (CAS) and Strip for Electrical Cable Shielding |

Fabrication Properties

|

|

Mechanical Properties of Gilding Metal

Product | Temper | Tensile Strength Minimum | Elongation Minimum | Hardness |

MPa | % | HV | ||

Sheet & Flats | Annealed | 80 Maximum | ||

Sheet & Flats <= 2.0mm | 1/2 Hard | 310 | 7 | 95-115 |

Sheet & Flats 2.1-3.2mm | 1/2 Hard | 280 | 7 | 85-110 |

Rod & Square Bar >6mm | M | 280 | 24 | |

Sheet & Flats <= 2.0mm | Hard | 360 | 3 | 110-135 |

Sheet & Flats 2.1-3.2mm | Hard | 320 | 3 | 100-125 |

Available Forms Austral Wright Metals can supply this alloy as sheet, strip and round bar.

General Description C22000 combines a rich golden colour with the best combination of strength, ductility and corrosion resistance of the plain copper-zinc alloys. It weathers to a rich bronze colour, and can be supplied in pre-patinated colours ranging from deep brown to green.

It has a lower rate of work hardening than the copper-zinc alloys with higher zinc content, such as 260 and 272. This is an advantage in multistage pressing applications without interstage annealing. It has excellent deep drawing characteristics and resistance to pitting corrosion when exposed to severe weather and water environments.

Typical applications. Architectural fascias, grillwork, jewellery, ornamental trim, vitreous enamel base, badges, door handles, escutcheons, marine hardware, munitions, primer caps, rotating bands, metallic bellows, pen, pencil and lipstick tubes etc.

Physical Properties of Gilding Metal

| Property | Metric Units | Imperial Units |

Melting Point (Liquidus) | 1045°C | 1910°F |

Melting Point (Solidus) | 1020°C | 1870°F |

Density | 8.80 gm/cm³ @ 20°C | 0.318 lb/in³ @ 68°F |

Specific Gravity | 8.80 | 8.80 |

Coefficient of Thermal Expansion | 18.4 x 10 -6 / °C (20-300°C) | 10.2 x 10 -6 / °F (68-392°F) |

Themal Conductivity | 189 W/m. °K @ 20°C | 109 BTU/ft³/ft/hr/°F @ 68°F |

Thermal Capacity (Specific Heat) | 376 J/kg. °K @ 20°C | 0.09 BTU/lb/°F @ 68°F |

Electrical Conductivity | 0.255 microhm?¹.cm?¹ @ 20°C | 44% IACS |

Electrical Resistivity | 3.92 microhm.cm @ 20°C | 10.3 ohms (circ mil/ft) @ 68°F |

Modulus of Elasticity (tension) | 115 GPa @ 20°C | 17 x 10 6 psi @ 68°F |

Modulus of Rigidity (torsion) | 44 GPa @ 20°C | 6.4 x 10 6 psi @ 68°F |

Poisson’s Ratio | 0.33 | 0.33 |

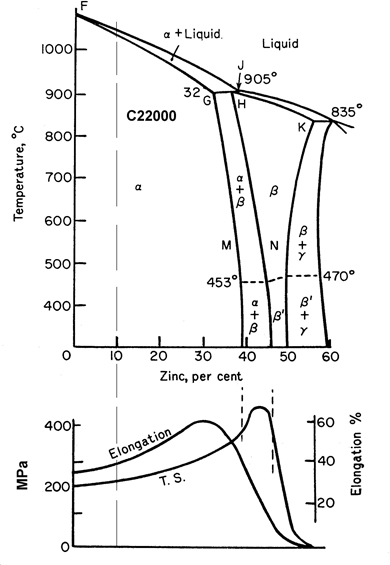

Phase Diagram & Mechanical Properties

Corrosion Resistance

As an alpha brass with low zinc content, C22000 has excellent corrosion in most media. It is less susceptible to stress corrosion cracking than the higher zinc brasses such as 70/30 brass C26000, and is not considered susceptible in marine atmospheres. However, it should not be used in contact with aqueous ammonia and amines.

C22000 should not be used with acetic acid, acetylene, brines, calcium chloride, moist chlorine, chromic acid, hydrochloric acid, mercury or its compounds, nitric acid and sodium hypochlorite.

Please consult Austral Wright Metals for advice on your specific application.