Copper Alloys Naval Brass C46400 – Austral Wright Metals

|

Product Data Sheet – Copper Alloys |

Naval Brass, Uninhibited UNS-C46400 |

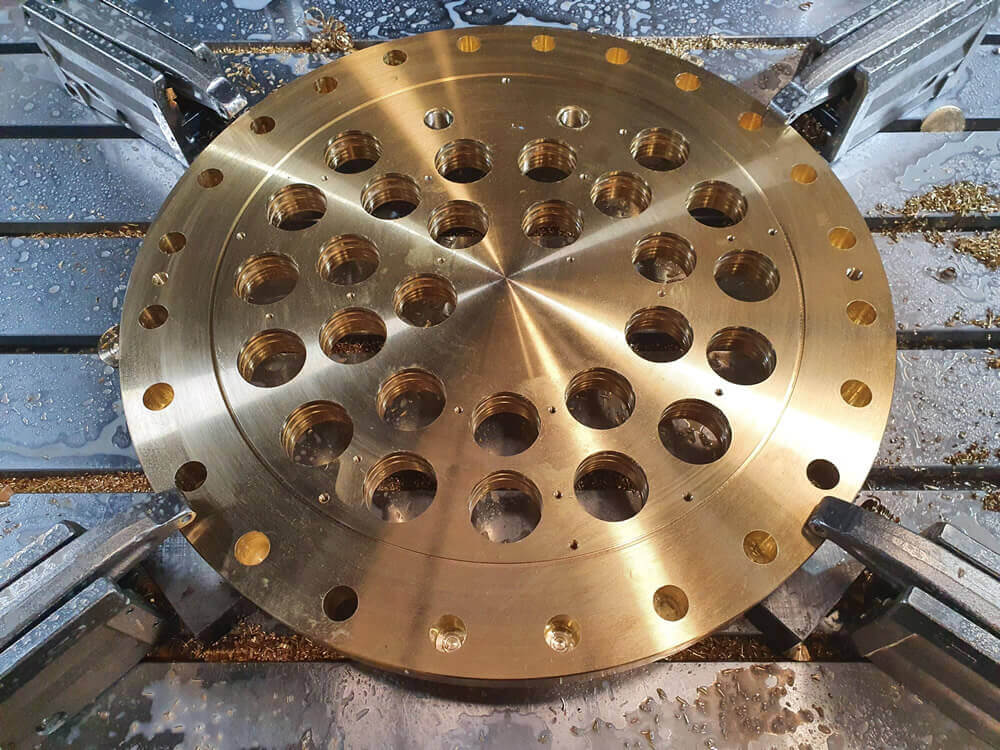

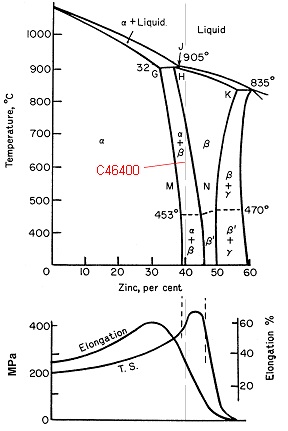

What is Naval Brass?Naval Brass is a 60:40 copper zinc alloy to which about 1% of tin has been added to improve the corrosion resistance, particularly to dezincification. The alloy is a two phase alpha-beta brass, or duplex brasses, hence has reasonably high strength with lower ductility than the single-phase 70:30 or alpha brass. It is used for structural applications and for forgings, especially where contact with sea water is likely to induce corrosion. The mechanical properties are almost indistinguishable from those of 60:40 brass C28000, although the tin addition tends to give slightly higher strength. C46400 can be readily hot worked, and can also be cold worked, but not as easily as the single phase alpha brasses. Typical ApplicationsC46400 naval brass alloys exhibit unique properties that lend itself suitable for the following applications:

Other gradesNaval brass can be sourced is grades/alloy composition other than C46400, these include C46200, C48200 and C48500, with these alloys more commonly found in bar and rod products. Chemical Composition(% maximum, unless shown as range or minimum)

Applicable Specifications

Room Temperature, 20°C

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mechanical Properties

Common Fabrication Processes

Blanking, Drawing, Forming and Bending, Heading and Upsetting, Hot Forging and Pressing, Hot Heading and Upsetting, Shearing

Fabrication Properties

|

** of C36000 (free cutting brass) |

Typical Uses

| Industry | Uses |

| Builders Hardware | Lock Pins |

| Electrical | Precision Shipboard Equipment |

| Fasteners | Nuts, Rivets, Bolts |

| Industrial | Hub Cones, Balls, Aircraft Turn Buckle Barrels, Valve Stems, Condenser Plates, Dies, Golf Ball Production, Pressure Vessels, Bearings, Bushings, Heat Exchanger Tube, Welding Rod, Structural Uses |

| Marine | Decorative Fittings, Propeller Shafts, Turn Buckles, Shafting, Marine Hardware, Propeller Shafts |

| Ordinance | Missile Components |

| Other | Baffle Plates & Flanges |

| Plumbing | Fittings |

Phase Diagram & Mechanical Properties

Corrosion Resistance

The addition of tin gives this alloy an inherent resistance to dezincification, further inhibiting the impingement by seawater at higher than normal temperatures. C46400 naval brass is also noted for its resistance to wear, fatigue, galling, and stress corrosion cracking.

C46400 has good corrosion resistance to weathering and good resistance to many waters. It was developed to resist the dezincification in sea water which may be encountered with plain 60:40 brass, C28000.

Low-copper alloys, such as naval brass appear to form thin, adherent surface films of corrosion products which are moderately protective.

C46400 should not be used in contact with ammonia, ammonia compounds or amines, as it may suffer stress corrosion cracking. It may also suffer stress corrosion cracking in atmospheric exposures.

Please consult Austral Wright Metals for advice on your specific application.

Marine Atmospheric Exposure

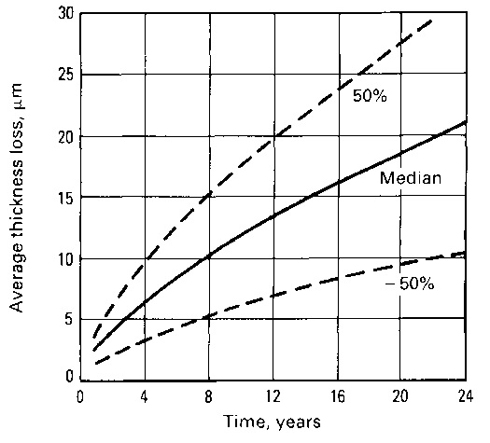

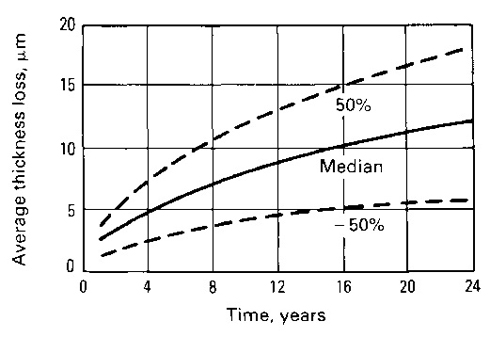

Copper alloys are often specified for marine atmospheric exposures because of the attractive and protective patina they form during the exposure by mild surface corrosion. The corrosion rate slows during the exposure.

Naval brass generally darkens to a deep chocolate brown colour. It is not expected to form the green patina often seen on alloys richer in copper, especially on material mounted vertically.

Differences between the corrosion rates of various alloys do exist, but they are usually less than the differences caused by the environment. Copper alloys can be classed into a group that corrodes at a moderate rate (high copper alloys, silicon bronze, tin bronze) and a group that corrodes at a slower rate (brass, aluminium bronze, nickel silver, copper nickel).

The average metal thickness loss, d, of the former group approximates to d = 0.1 t2/3, and of the latter group to d = 0.1 t1/3, where t is the exposure time.

The surface can be artificially bronzed to produce by the patina, please contact Austral Wright Metals for details. Both artificial and naturally patinated surfaces will continue to darken unless washed hot soapy water, rinsed, dried and treated with lemon oil, boiled linseed oil or castor oil. The surface will take on a mild lustre.

This sequence of washing and oiling should be repeated at about yearly intervals to maintain the metal in good condition.

|  | |

| Moderate corrosion rate group (high copper alloys, silicon bronze, tin bronze) | Low corrosion rate group (brass, aluminium brass, nickel silver, copper nickel) |

The surface can be artificially bronzed to produce by the patina, please contact Austral Wright Metals for details. Both artificial and naturally patinated surfaces will continue to darken unless washed hot soapy water, rinsed, dried and treated with lemon oil, boiled linseed oil or castor oil. The surface will take on a mild lustre.

This sequence of washing and oiling should be repeated at about yearly intervals to maintain the metal in good condition.

Physical Properties

| Property | Metric Units | Imperial Units |

Melting Point (Liquidus) | 899°C | 1650°F |

Melting Point (Solidus) | 888°C | 1630°F |

Density | 8.41 gm/cm³ @ 20°C | 0.304 lb/in³ @ 68°F |

Specific Gravity | 8.41 | 8.41 |

Coefficient of Thermal Expansion | 21.2 x 10 -6 / °C (20-300°C) | 11.8 x 10 -6 / °F (68-572°F) |

Themal Conductivity | 120 W/m. °K @ 20°C | 67 BTU/ft2/ft/hr/°F @ 68°F |

Thermal Capacity (Specific Heat) | 377.1 J/kg. °K @ 293°K | 0.09 BTU/lb/°F @ 68°F |

Electrical Conductivity | 0.152 MegaSiemens/cm@ 20°C | 26 % IACS @ 68°F |

Electrical Resistivity | 6.63 microhm.cm @ 20°C | 39.9 ohms -cmil/ft@ 68°F |

Modulus of Elasticity (tension) | 103,400 MPa | 15,000 ksi |

Modulus of Rigidity (torsion) | 38,610 MPa | 5,600 ksi |

Tempers Most Commonly Used

|

|