Nickel Alloys Incoloy Alloy 800 N08800 – Austral Wright Metals

| |

Product Data Sheet Nickel Alloys | |

Alloy 800™, 800H™, 800HT™ UNS-N08800, N08810, N08811 | |

Incoloy® Alloy 800™ is widely used in equipment that must have high strength and resistance to oxidation, carburisation and other harmful effects of high temperature exposure. For service requiring optimum creep and rupture properties, Incoloy 800H or 800 HT are used. The high contents of nickel and chromium in the alloys also give good corrosion resistance. Chemical CompositionASTM B407 – Seamless Pipe & Tube

Specified Minimum Mechanical PropertiesASTM B407 – Seamless Pipe & Tube

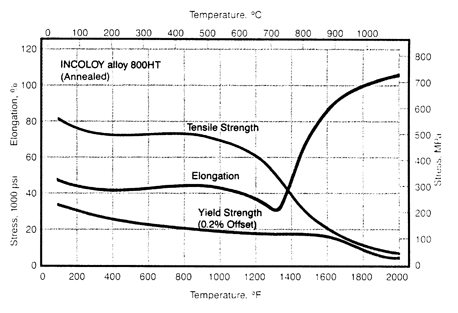

Incoloy 800 is a solid solution strengthened alloy of nickel, chromium and iron with small additions of aluminium and titanium. Incoloy 800H and Incoloy 800HT are developments of Incoloy 800, which give better performance at high temperature. ASME design codes give significantly higher design strengths for Incoloy H and HT than Incoloy 800, and allow their use to higher temperatures. AS1210 prequalifies Incoloy 800 for use to 800°C. ASME specifications allow the use of Incoloy 800 to 815°C, and of Incoloy 800H and 800HT to 982°C. Typical ApplicationsThermal processing equipment in industrial applications, such as baskets, trays, and fixtures. In chemical or petrochemical processing it is used for heat exchangers and piping systems in nitric acid media, especially where resistance to chloride stress corrosion cracking is required. DescriptionIncoloy 800/800H/800HT are solid solution nickel chromium iron alloys with small additions of aluminium and titanium to improve corrosion and oxidation resistance. They are used for high temperature service, where resistance to oxidation and carburisation are required. For optimum stress rupture properties, or for pressure vessel service above 815°C, Incoloy 800H or Incoloy 800HT should be used. AvailabilityAustral Wright Metals can supply these alloys as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, fittings, condenser & heat exchanger tube, forgings and forging stock. Oxidisation ResistanceThe chromium and nickel contents of the alloy give excellent oxidation resistance, good resistance to carburisation and resistance to sulphidation at low concentrations of oxidising and reducing sulphur. The alloy also has reasonable resistance to nitridation in cracked ammonia, but falls short of the resistance of Inconel 600. Variation of Tensile Properties with Temperature

Corrosion ResistanceIncoloy 800/800H/800HT is generally free from both chloride stress corrosion cracking and intergranular corrosion caused by sensitisation. The alloy can be used in sea water. Incoloy 800/800H/800HT has resistance to acids similar to austenitic stainless steels. It has excellent resistance to both oxidising and non oxidising salts, except for halide salts, where pitting may occur. Please consult Austral Wright Metals for advice on your specific application. FabricationIncoloy 800/800H/800HT can be readily hot worked. Forging is finished above 870°C, and air cooled. The work is then solution annealed. The alloys can be cold formed similarly to stainless steel but deformation forces are higher. MachinabilityIncoloy 800/800H/800HT are “C” class alloys, difficult to machine. Heavy machines, sharps, slow speeds and deep cuts to remove the work hardened layer are needed. WeldabilityIncoloy 800/800H/800HT are readily welded by the SMAW (manual), GMAW (MIG), GTAW (TIG) and SAW processes. Preheat or post heat and post weld heat treatment are not needed. Contamination of the weld pool should be prevented. Argon is used as the shielding gas. Welding Consumables

Heat TreatmentIncoloy 800 is solution annealed at 980°C, then rapidly cooled. Appreciable grain growth will occur if this temperature is exceeded. Incoloy 800H and 800HT are annealed at is 1150 – 1200°C to grow the grain size to ASTM 5. Equivalent Specifications

Physical Properties

ASTM Product Specifications

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||