Nickel Alloys Monel 400 N04400

|

Product Data Sheet – Nickel Alloys |

Monel 400 UNS-N04400 |

Monel K-500 is a versatile nickel copper alloy with good strength and toughness, combined with outstanding corrosion resistance. Monel R-405 is a free cutting version with similar properties. Chemical CompositionASTM B127 – Plate, sheet & strip

Equivalent Specifications

ASTM Product Specifications

Specified Minimum Mechanical PropertiesASTM B127 – Plate, sheet & strip

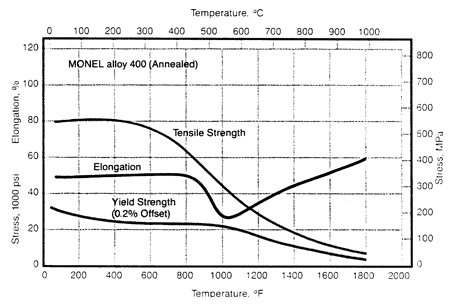

Available Forms Austral Wright Metals can supply Monel 400 as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, condenser and heat exchanger tube, welding fittings, forgings and forging billet, wire. Monel R-405 is available as rod and bar. General Description Monel 400 is a nickel copper alloy with good strength and ductility, good weldability and excellent resistance to corrosion. It is tough over a wide range of temperatures. It is often used in marine applications. Corrosion rates in strongly agitated and aerated sea water are extremely low. The alloy has useful properties to 540°C in oxidising atmospheres and higher temperatures in reducing conditions. Monel 400 is readily welded and brazed. Typical applications Chemical plant, valves and pumps, pump & propeller shafts, marine fixtures and fasteners, electrical components, springs, gasoline & fresh water tanks, petroleum stills, process vessels & piping, boiler feedwater heaters and other heat exchangers, deaerating heaters. Physical Properties

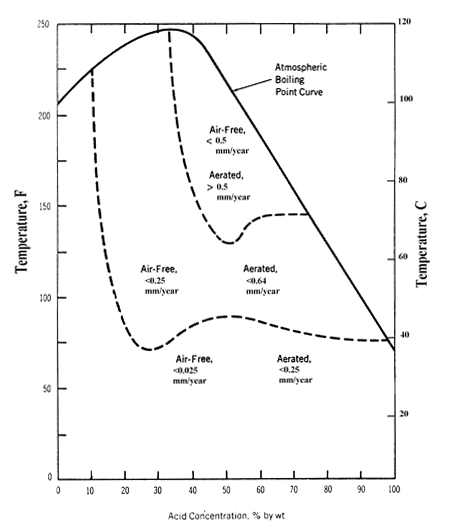

Corrosion ResistanceMonel 400 is generally more corrosion resistant that both of the major constituents nickel and copper. It is highly resistant to chlorinated solvents, glass etching agents, sulphuric, hydrofluoric and many other acids, and practically all alkalies. The alloy gives excellent service in sea water under high velocity conditions, where resistance to cavitation and erosion are important. Corrosion rates in strongly agitated and aerated sea water are extremely low. It is generally free from chloride stress corrosion cracking, but only annealed material resists stress cracking in the presence of mercury or mercury salts, and in moist, aerated hydrofluoric acid vapour. It should not be used for nitric acid service. Please consult Austral Wright Metals for specific advice on your application. Pressure VesselsAS1210 & ASME Boiler & Pressure Vessel Code pre-qualify Monel 400 for use in pressure vessels up to about 475°C. FabricationMonel 400 can be readily hot worked, with lower forces than many steels. The alloy can easily be cold formed, with forces between those of carbon steel and grade 304 stainless steel.

MachinabilityMonel 400 is easy to machine (class B). Sharp tools, slow speeds and deep uninterrupted cuts to remove the work hardened layer are needed. Monel R-405 is a free cutting version of Monel 400, for rapid production in automatic screw machines. Toughness, strength and corrosion resistance are very similar to Monel 400.

WeldabilityMonel 400 is readily welded by GMAW (MIG), GTAW (TIG), SMAW (manual) and SAW processes. Preheat, post heat and post weld heat treatment are not required. The area around the weld must be clean to prevent contamination of the weld pool. Argon shielding gas is used. Heat TreatmentMonel 400 is annealed at 870–980°C, cooling rate not critical. Grain growth is rapid in this alloy, so use the lower end of the temperature range and minimal time to retain good strength. Stress relief, if required, is at 540-570°C. Stress equalising cold worked material at 300°C markedly increases the proof stress, without affecting other properties. Filler Metal SelectionSelf Welds

|