Titanium Alloy Grade 7

|

Product Data Sheet – Titanium Alloys |

Titanium Grade 7 UNS-R52400 |

Titanium Alloy Grade 7 has outstanding corrosion resistance and useful strength at low density. A small addition of palladium has been made to this alloy for a substantial increase in corrosion resistance. Typical ApplicationsMost of the applications of this grade are in the chemical industries. The most common uses are reactor autoclaves, piping and fittings, valves, heat exchangers and condensers. Chemical CompositionASTM B338 – Seamless & welded

Specified Minimum Mechanical Properties(ASTM B338 – Seamless & welded titanium & titanium alloy tubes for condensers & heat exchangers)

DescriptionTitanium grade 7 is a corrosion resistant alpha titanium alloy with similar mechanical properties to the commercially pure grades. It has a small palladium addition to improve corrosion resistance, particularly in mineral acids and strong brines. It is used mildly reducing or fluctuating conditions. At room temperature it is an alpha alloy. It transforms to beta phase at 913°C, and the alpha phase returns on cooling 890°C. Titanium is reactive, with a very high affinity for oxygen, which forms a skin of very stable and highly adherent oxide. The skin gives excellent corrosion resistance, despite the reactivity of the metal. The oxide layer forms spontaneously and on exposure to the atmosphere. However, when new parent metal is exposed to anhydrous conditions or in the absence of air, rapid corrosion may occur. Care should also be taken if titanium is to operate in contact with hydrogen, as hydrogen embrittlement from hydride formation can increase strength, with loss of ductility. AvailabilityAustral Wright Metals can supply this alloy as plate, sheet and strip, rod and bar, seamless and welded pipe, weld fittings, seamless and welded tube, forging billet and forgings. It is widely used as tube in condensers and heat exchangers. Pressure VesselsAS1210 & ASME Boiler & Pressure Vessel Code pre-qualify titanium 7 for use in pressure vessels up to 300°C. AS4041 Pressure Piping qualifies the alloy to 325°C. Corrosion ResistanceTitanium has excellent resistance to general corrosion, with low or negligible loss rates in many media. See Austral Wright Metals data sheet “Corrosion of Titanium and alloys” for more detail. The table on the next page gives examples of the improved corrosion rate of Grade 7 compared to commercial purity Grade 2. Physical Properties

Comparative Corrosion Ratesfor Ti-Pd, Grade 7, and Unalloyed Titanium Grade 2

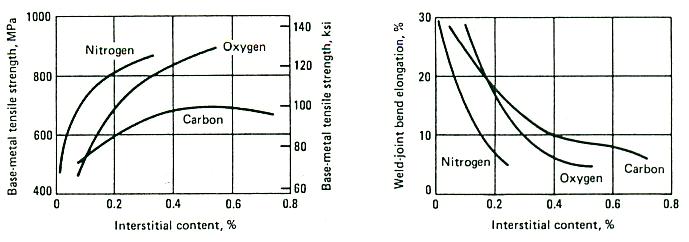

FabricationTitanium grade 7 is forged by conventional processes within the narrow temperature range 815 – 900°C. Titanium and its alloys generally are more difficult to forge than both aluminium and alloy steels, but grade 7 is one of the easier grades. Hot forging leaves a thick, extremely hard outer layer of titanium oxide on the surface. This layer is called “alpha case” and is usually removed by pickling in a mixture of nitric and hydrofluoric acids. As supplied, titanium alloys are usually annealed, and can be readily cold formed in conventional machines using standard methods. When cold formed the oxide layer “alpha case” does not form and pickling is not needed, except to remove embedded carbon steel pickup, which can cause pitting corrosion. MachinabilityTitanium grade 7 is readily machinable by conventional methods. It is comparable to austenitic stainless steels for machinability. Like stainless steel, titanium has a low thermal conductivity and heat dissipation is worse than for copper alloys, so generous use of coolant is recommended. Sharp tools are essential. WeldabilityTitanium grade 7 is readily weldable by GMAW and GTAW processes. Preheat or post weld heat treatment are not needed. The area immediately surrounding the welds must be CLEAN, free from all grease and shop dirt, including pencil marks. Abrasive cleaning can be used, as can solvent cleaning and pickling with a mixture of nitric and hydrofluoric acids. A trailing gas shield must be used in addition to the normal welding torch gas shield, to prevent heavy oxidation during cooling. Matching filler metal to AWS ERTi-7 is used. The gas shield must be low in hydrogen, oxygen and nitrogen, all of which readily dissolve in titanium and cause embrittlement. Effects of Interstitial Elementson the strength and ductility of unalloyed aluminium

Heat TreatmentTitanium grade 7 is annealed at 670 – 750°C, still air cooled. Pickling to remove the “alpha case” may be needed before further fabrication or machining. Stress relief at 480 – 595°C, air cooled, may be required to improve dimensional stability for critical components. ASTM Product Specifications

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||