Stainless Steel AWM-404GP

|

Product Data Sheet – Stainless Steel |

General Purpose Ferritic Grade AWM 404GP® |

Available exclusively from Austral Wright Metals! New generation general-purpose ferritic grade AWM 404GP® can be used to replace the workhorse austenitic grade 304 in most applications. It is a corrosion resistant ferritic stainless steel with excellent strength, toughness, fabrication characteristics and weldability. The general corrosion resistance of AWM 404GP® is at least as good as grade 304, with better resistance to atmospheric corrosion, stress corrosion cracking and sensitization to intergranular corrosion. Typical Applications Benchwork, cold-water tanks, whitegoods, refrigeration cabinets, chemical and food processing, water treatment plant, street furniture, electrical cabinets. AWM 404GP® can be substituted for 304 in most applications except structures and pressure vessels. Chemical CompositionGrade AWM 404GP® compared to Grade 304

Mechanical PropertiesGrade AWM 404GP® compared to Grade 304

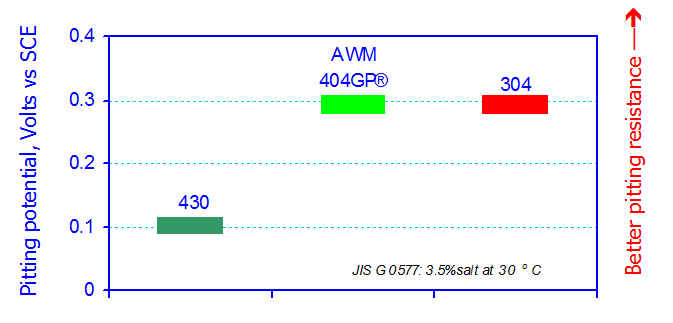

DescriptionGrade AWM 404GP® contains 21% of chromium and 0.5% of copper, which give it excellent resistance to corrosion in many environments. AWM 404GP® has at least the corrosion resistance of grade 304, and is increasingly replacing 304 in sheet metal applications. Many users of AWM 404GP® make significant savings from the ease of fabrication – ferritic grades give less tool & machine wear than 304. Better quality products, with crisper, neater bends are achievable with AWM 404GP®. AWM 404GP® is magnetic, which does not affect the excellent corrosion resistance given by the high chromium content. Thermal expansion is lower, so there is less thermal distortion of panels in fabrication and in service. AvailabilityAustral Wright Metals stock this grade as sheet and coil in thicknesses 0.55, 0.7, 0.9, 1.2, 1.5 and 2.0 mm, all 1219 mm wide. 914 mm wide is available in some thicknesses. 2B and No 4 finish. The finishes are brighter than for 304 – ferritic grades have a brighter surface finish than austenitic grades. The 2B finish may be variable across the width and should not be used where this is unacceptable. SpecificationsAWM 404GP® is included in JIS G4305 Cold-rolled stainless steel plate, sheet and strip, as grade SUS443J1 and in ASTM A240 Chromium and Chromium-Nickel Stainless Steel Plate, Sheet and Strip for Pressure Vessels and for General Applications as grade S44330. Corrosion ResistanceThe chemical composition of AWM 404GP® gives it a higher Pitting Resistance Equivalent (PRE) than 304, which indicates at least equivalent pitting corrosion resistance. Pitting is the form of corrosion stainless steels are often least resistant to. Laboratory tests and service experience have not identified circumstances in which the corrosion resistance of AWM 404GP® is inferior to 304, except pitting propagation rates, which are 3 – 4 times faster. Unfortunately, once initiated, pitting corrosion propagation is rapid for both grades, and practical selection of stainless steels aims to avoid pitting corrosion rather than achieve low propagation rates. Resistance to the initiation of pitting corrosion in artificial seawater at 30ºCShows equivalent resistance to pitting corrosion initiation for the general purpose grades 304 and AWM 404GP®

Atmospheric Corrosion – Actual Exposure Test

Physical PropertiesGrade AWM 404GP® compared to Grade 304

ToughnessAWM 404GP®has the same ferritic microstructure as carbon steel, so undergoes a ductile-to-brittle fracture mode transition at low temperatures. AWM 404GP® is tough in the welded condition down to 0°C, and can be used for non-structural purposes at lower temperatures. Pressure VesselsAWM 404GP® can be used for pressure vessels at elevated temperatures, but it is not pre-qualified in pressure vessel codes. Heat TreatmentAWM 404GP® is not hardenable by heat treatment. Heat treatment is rarely required in sheet metal applications, but AWM 404GP® can be annealed at 820 – 900°C, rapid air cool. Pickling in hydrofluoric acid is required to restore full corrosion resistance. High Temperature ServiceThe high chromium content of AWM 404GP® gives excellent oxidation and sulphidation resistance, and similar grades are used extensively in automotive muffler systems. AWM 404GP® can be used in air up to 980°C for continuous service, 1035°C for intermittent service. The strength of ferritic grades above about 600°C is generally less than that of austenitic grades. Where later ambient temperature toughness and corrosion resistance are important, the service temperature should be restricted to 400°C to avoid precipitation reactions. CleanabilityAWM 404GP® is excellent for food equipment, where cleanability for the removal of bacteria is vital. AWM 404GP® resists corrosion by food and cleaning chemicals, and harbours very low levels of bacteria after cleaning. Fabrication and FormabilityAs a ferritic stainless steel, AWM 404GP® behaves like carbon steel (G300). Bends are neater, with low springback and forming loads. Wear on cutting and forming tools is typically 3 – 5 times better. Cutting tool clearances are similar to carbon steel. The minimum radius for bending is 1t. Deep drawability is better than 304, but stretch capability is lower. Please consult Austral Wright Metals for deep drawing applications. MachinabilityAWM 404GP® is easier than 304 to machine due to lower work hardening rate and better thermal properties. Cleaner cuts and flatter panels are obtained, with better cutting tool life. WeldabilityAWM 404GP® can be welded by the common methods (TIG, MIG, spot, seam), without preheat, post heat or post weld heat treatment. Heat input needs to be 10 – 30% higher than for grade 304 as heat is conducted away from the weld pool more quickly by AWM 404GP®. Manual Metal Arc welding (MMAW or stick welding) is not recommended – AWM 404GP® is used in light gauges, not easy to stick weld. AWM 404GP® can be TIG welded without filler metal, or with 308L(Si), 309L(Si) or even 316L(Si) wire. Avoid introducing carbon into the weld by degreasing before welding – degreasing is as important with AWM 404GP® as it is with aluminium. Gas shielding must be excellent – use argon, or argon plus helium or up to 3% CO2. Never use nitrogen or hydrogen in welding or backing gases. For best pickling after welding, ensure oxidation is minimised and use the pickling paste for longer than with 304. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||