Copper Alloys Nickel Silver C75700 – Austral Wright Metals

|

Product Data Sheet – Copper Alloys |

Copper Alloys Nickel Silver 12% Nickel Silver UNS-C75700What Is Nickle Silver?Alloy C75700 (12% nickel silver), also known as German Silver, was a material introduced as a cheaper lower nickel content alternative to the 18% nickel silver alloy, C77000. Like 18% nickel silver, its principal applications are in spring components produced from hard rolled tempers where corrosion and termite resistance are required. Accordingly, much of 12% nickel silver produced is used in the telecommunications industry as an alternative to 18% nickel silver alloy. The performance is almost equivalent except in extra hard temper where 18% nickel silver alloy has the advantage of higher strength and corrosion resistance but at a higher cost. In most other respects and applications the alloy can be regarded as interchangeable except in some jewellery and decorative applications where 18% nickel silver alloy is sometimes preferred for its slightly higher white silver colour.

General Description 12% nickel silver takes a brilliant polish and has good resistance to corrosion in rural, industrial and marine atmospheres and in freshwater. Since it has good cold formability and an attractive soft ivory-white colour, it is often used for decorative applications. The alloy is often silver plated, when it may be stamped EPNS (electro plated nickel silver). Alloy 12% nickel silver itself does not contain silver. It takes its name from the similarity of its appearance when polished to silver, although it does not have the corrosion resistance of the latter. 12% nickel silver is a copper nickel zinc alloy. The crystal structure is the face centred cubic alpha phase, and hence the alloy has a good combination of strength, hardness and ductility. |

Chemical CompositionAS2738-2000

Equivalent Alloy Specifications

Australian Product Specifications

Fabrication Properties

Mechanical PropertiesAS1566 Rolled Flat Products

Copper Alloys Nickel Silver C75700 Available Forms Austral Wright Metals can supply this alloy as coil or sheet. See the Austral Wright Metals Product Catalogue for standard stock sizes. General Description 12% nickel silver takes a brilliant polish and has good resistance to corrosion in rural, industrial and marine atmospheres and in fresh water. Since it has good cold formability and an attractive soft ivory-white colour, it is often used for decorative applications. The alloy is often silver plated, when it may be stamped EPNS (electro plated nickel silver). Alloy C75700 itself does not contain silver. It takes its name from the similarity of its appearance when polished to silver, although it does not have the corrosion resistance of the latter. C75700 is a copper nickel zinc alloy. The crystal structure is the face centred cubic alpha phase, and hence the alloy has a good combination of strength, hardness and ductility. Typical Uses for Nickel SilverDecorative. Holloware, spoons and forks, watch cases, jewellery, medallions, “objets d’art”, pressed, spun or deep drawn items, usually silver plated.

Physical Properties

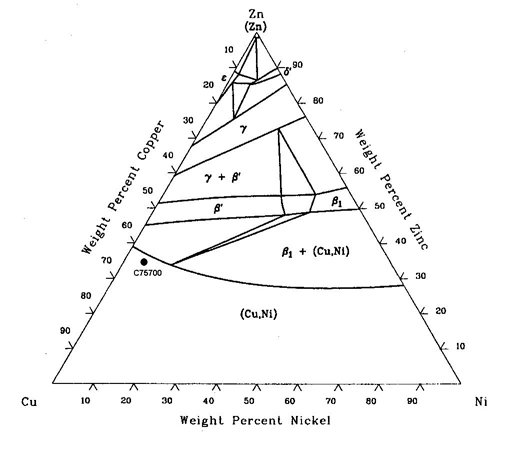

Benefits of Using Nickle SilverDoes Nickel Silver Tarnish?Whilst 12% nickel silver has very high corrosion resistance, it will tarnish in certain environments. Mostly this will be a mild tarnish which is easily removed with a gentle liquid hand polish. Heavier mechanical polishing can produce a mirror like surface. Corrosion Resistance of Nickle SilverC75700 12% nickel silver has good corrosion resistance to weathering. It is frequently used in decorative applications, where it undergoes little tarnishing in service. If atmospheric corrosion does occur after prolonged exposure without cleaning in an aggressive marine environment, the corrosion products are likely to be green to brown in colour. Exposure tests 25 metres from a surf beach have indicated a likely thickness loss due to corrosion of about 1 mm per year. C75700 12% nickel silver should not be used in contact with ammonia or ammonia compounds, as it may suffer stress corrosion cracking. Beware of corrosion inhibitors in piping systems containing carbon steels, which should be checked for compatibility with alloy 12% nickel silver. Please consult Austral Wright Metals for advice on your specific application. Phase Diagram of C75700Isothermal Section at 20°C

Corrosion ResistanceC75700 has good corrosion resistance to weathering. It is frequently used in decorative applications, where it undergoes little tarnishing in service. If atmospheric corrosion does occur after prolonged exposure without cleaning in an aggressive marine environment, the corrosion products are likely to be green to brown in colour. Exposure tests 25 metres from a surf beach have indicated a likely thickness loss due to corrosion of about 1 mm per year C75700 should not be used in contact with ammonia or ammonia compounds, as it may suffer stress corrosion cracking. Beware of corrosion inhibitors in piping systems containing carbon steels, which should be checked for compatibility with alloy C75700. Please consult Austral Wright Metals for advice on your specific application. |